Case studies

Sealing seam inspection for cheese packaging with thermoforming trays

Food & BeveragesPackaging

Quality control

2D technology

Initial situation

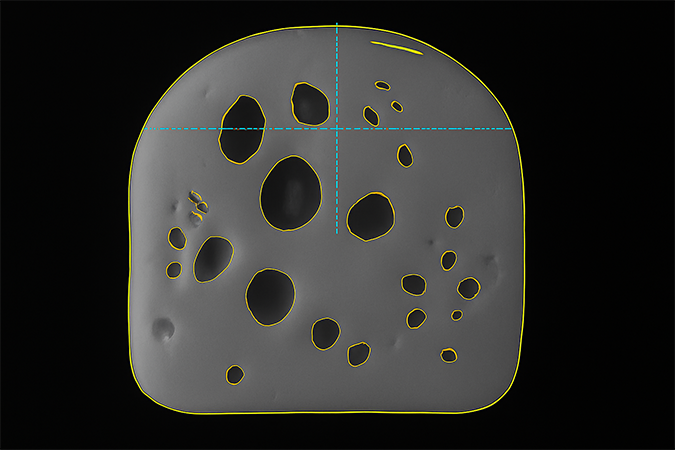

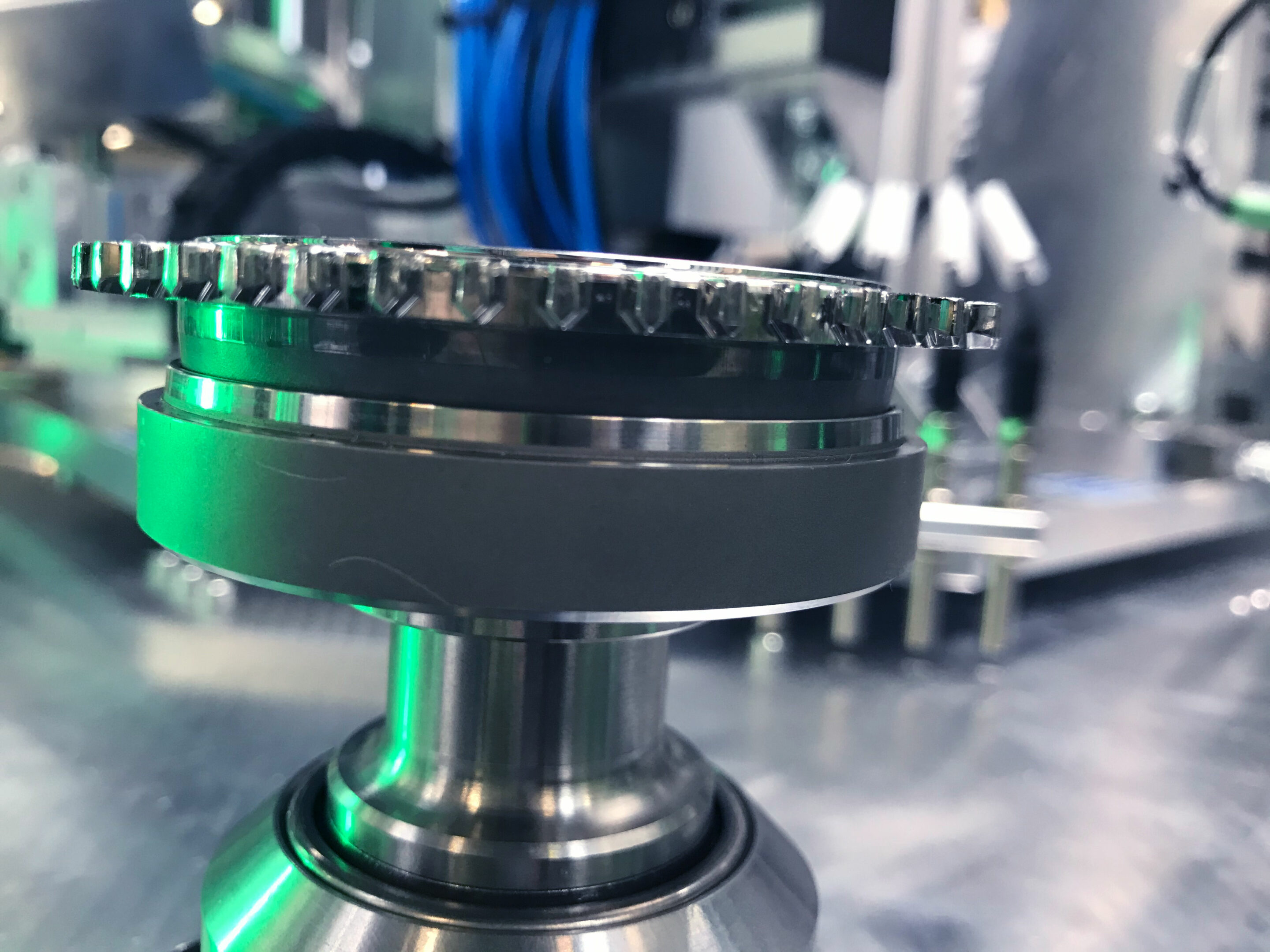

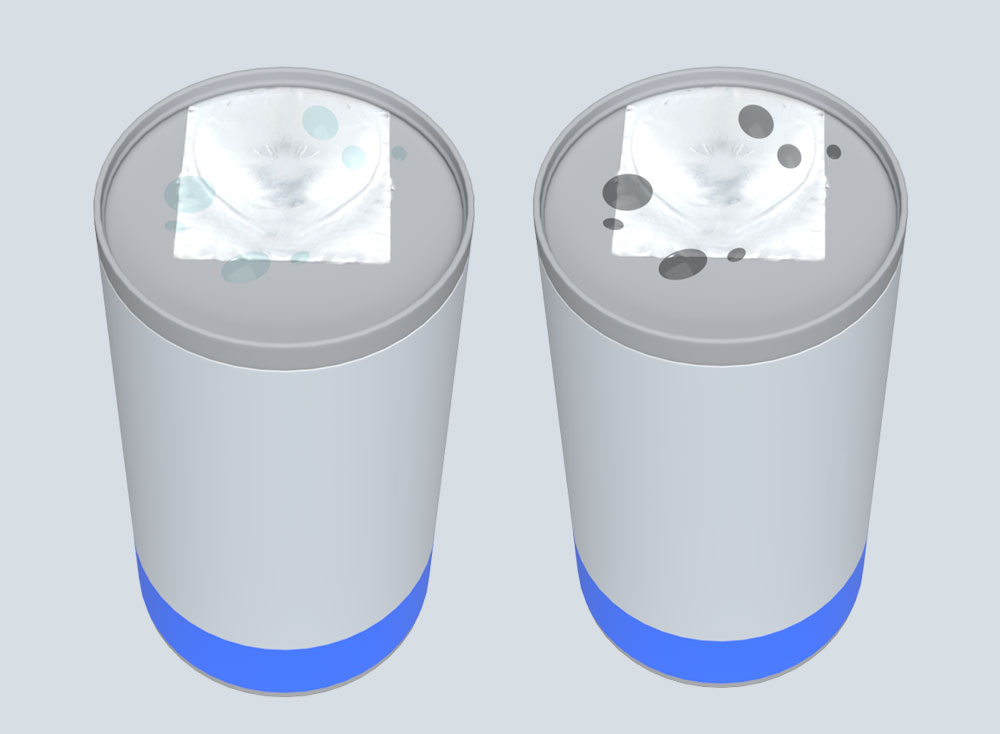

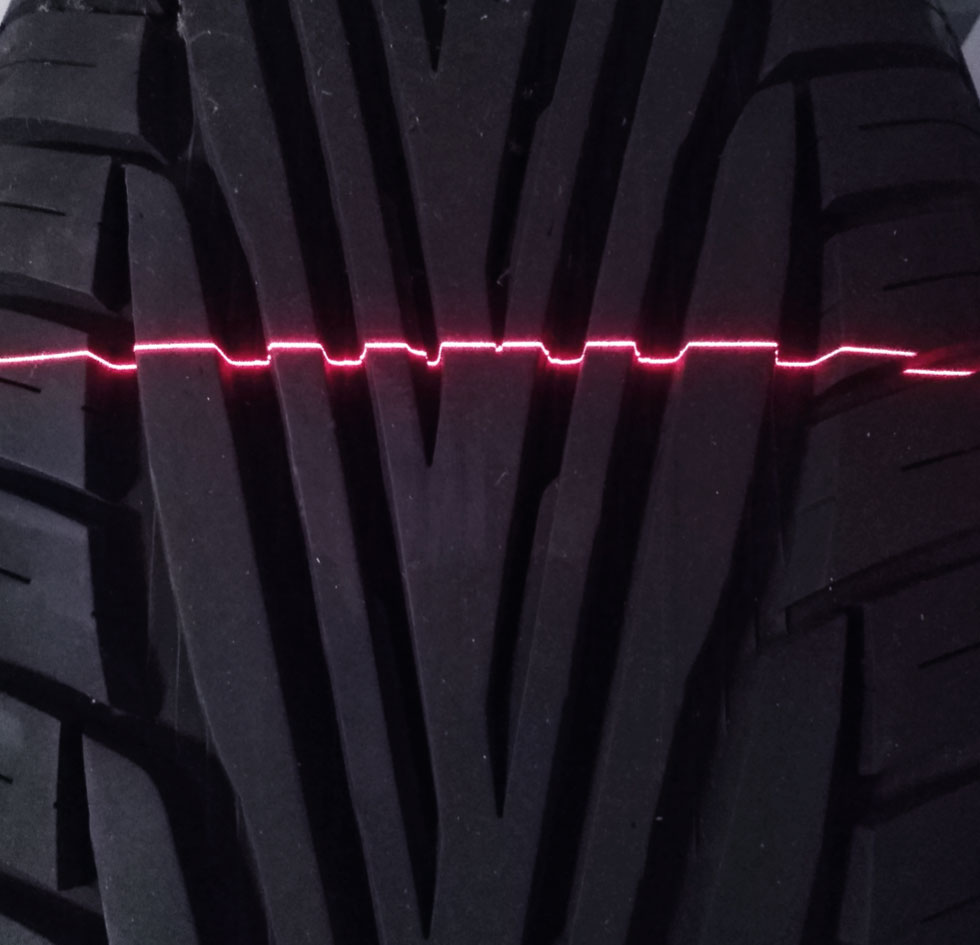

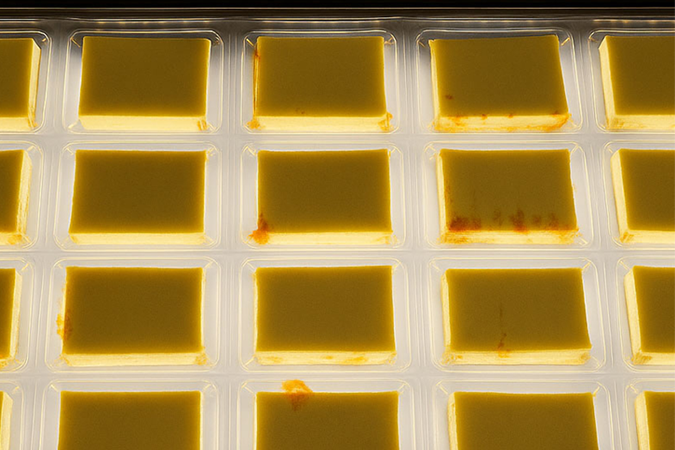

In modern packaging lines for cheese products, sealing takes place in thermoformed trays made of transparent or milky-white film. A flawless sealing seam is crucial for product safety and quality. However, cheese residues or aroma leaves in the seam area can lead to leaks, which entails considerable risks for shelf life and product protection. To prevent this, a camera-based inspection system is required that guarantees reliable inspection even with varying tray formats.

Implementation

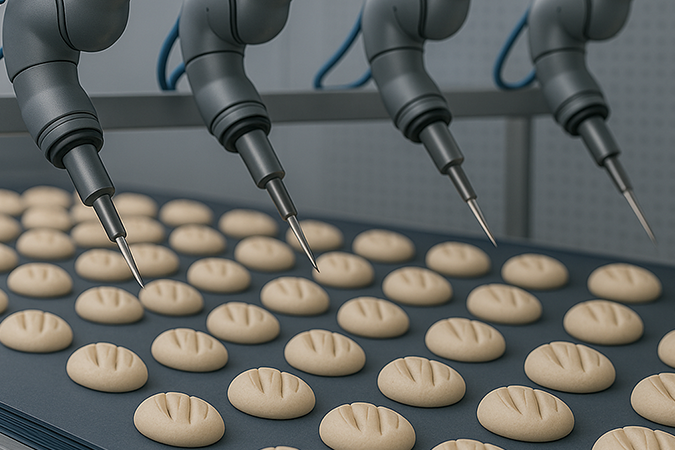

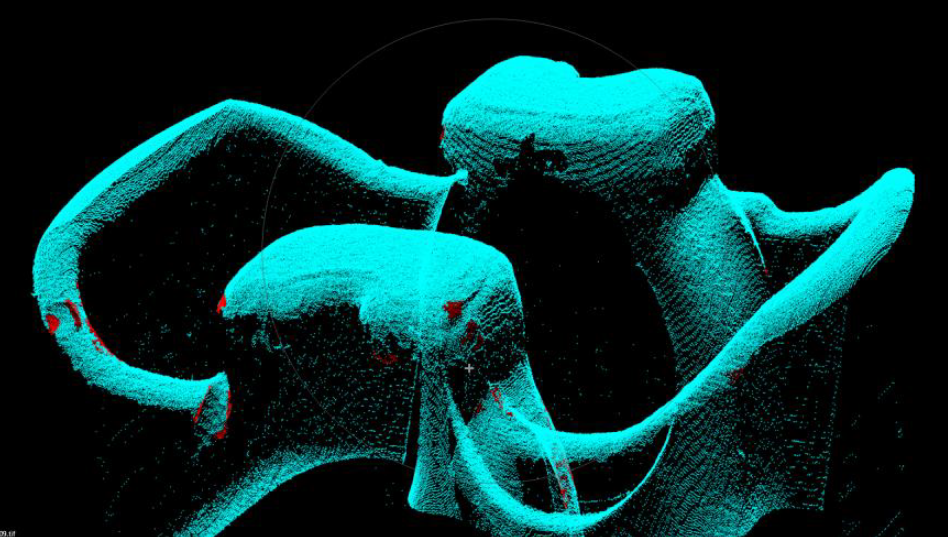

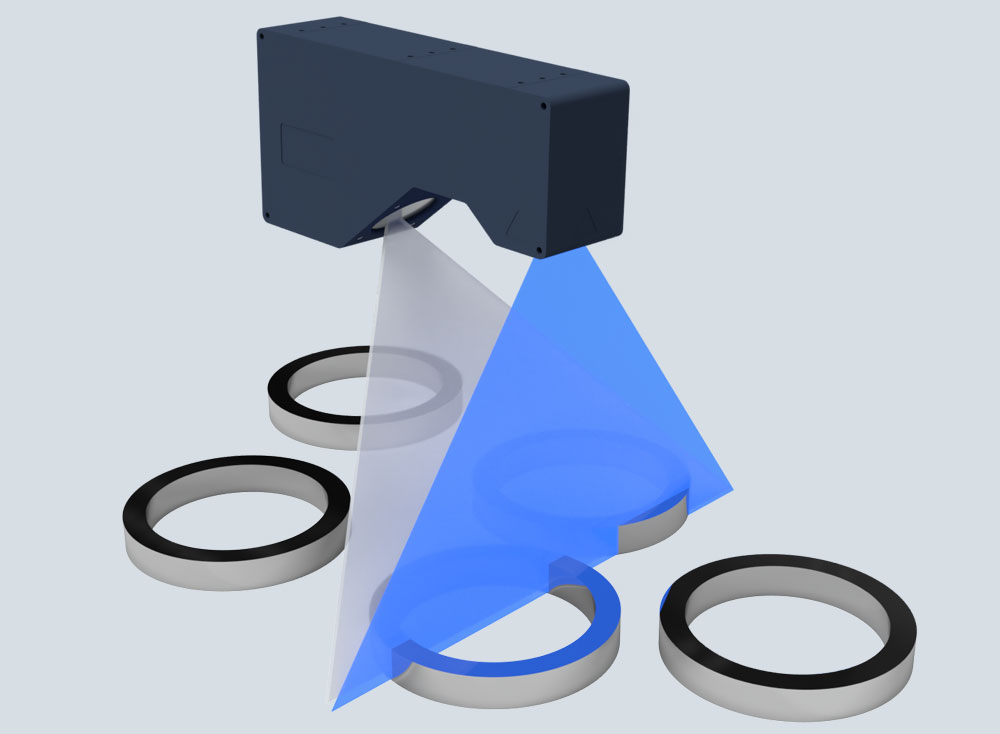

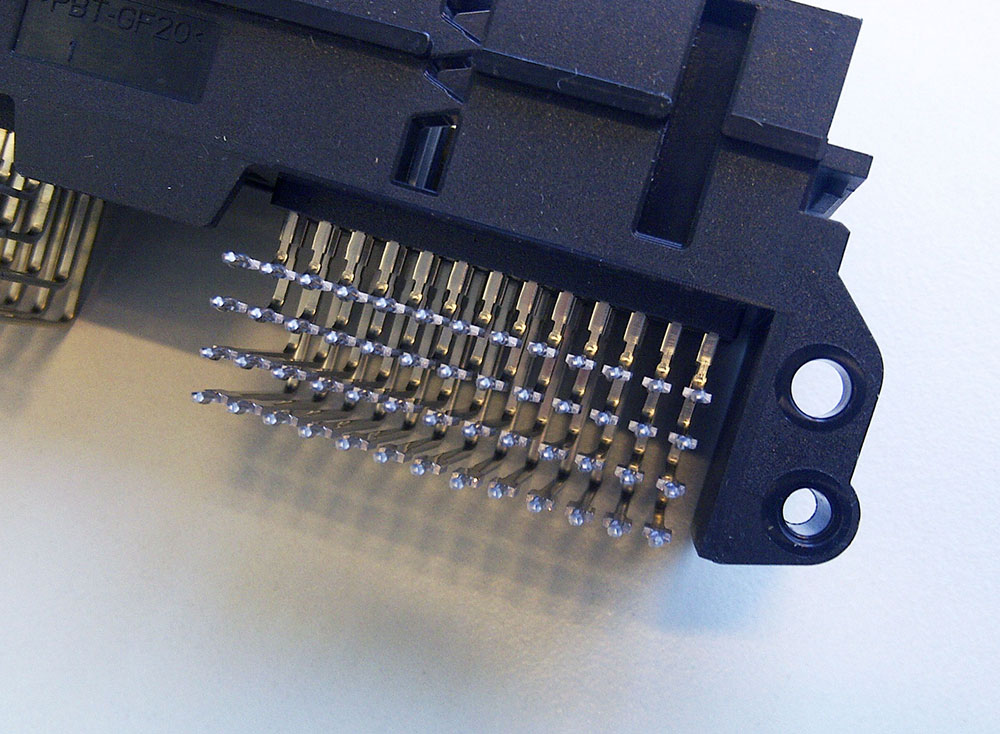

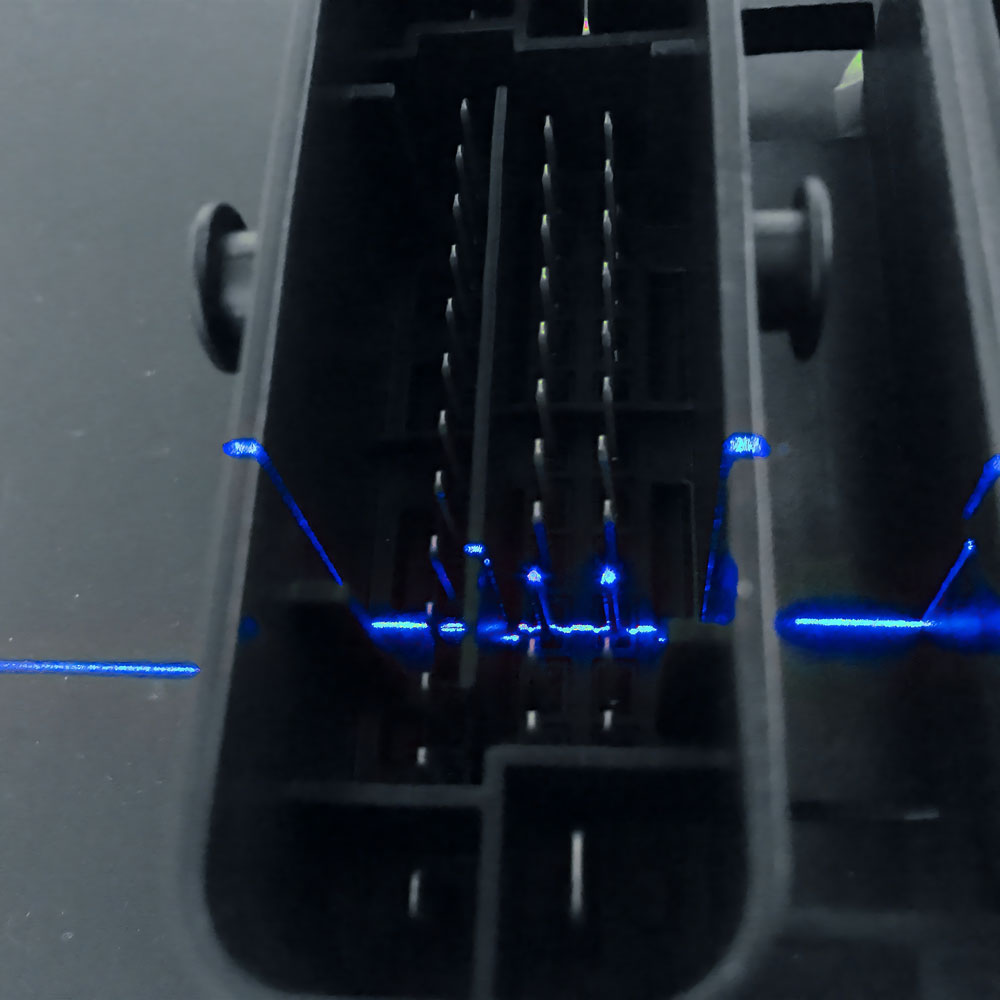

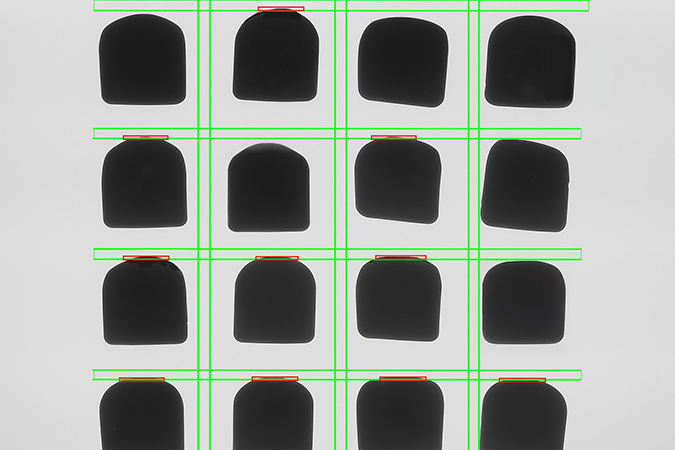

A high-resolution 2D camera system with transmitted light technology is used for inline inspection of the seal seam. Each packaging unit is recorded while stationary and evaluated within a very short time. Even the smallest particles or foreign objects in the seam area are reliably detected. Defects are detected visually and displayed immediately on the monitor. Stored programs allow product changes to be implemented quickly and reliably, minimizing set-up times and reducing the risk of errors. The system can be seamlessly integrated into existing lines via standardized interfaces.

Parameters

- Particle detection from 1 mm in the sealing area

- Protection class IP67, stainless steel housing

Customer benefits

The system enables stable and format-independent quality assurance during operation. Critical seal seam defects are detected at an early stage, reducing waste and avoiding rework. Thanks to the easy adaptability to new packaging formats, the production line remains flexible and efficient. The hygienic design and high scalability make the solution ideal for demanding production environments in the food industry.

Your contact person

Christian Merten

Head of Sales

Email: c.merten@aku.eu

Phone: +49 151 / 259 190 10

Case studies

You might also be interested in:

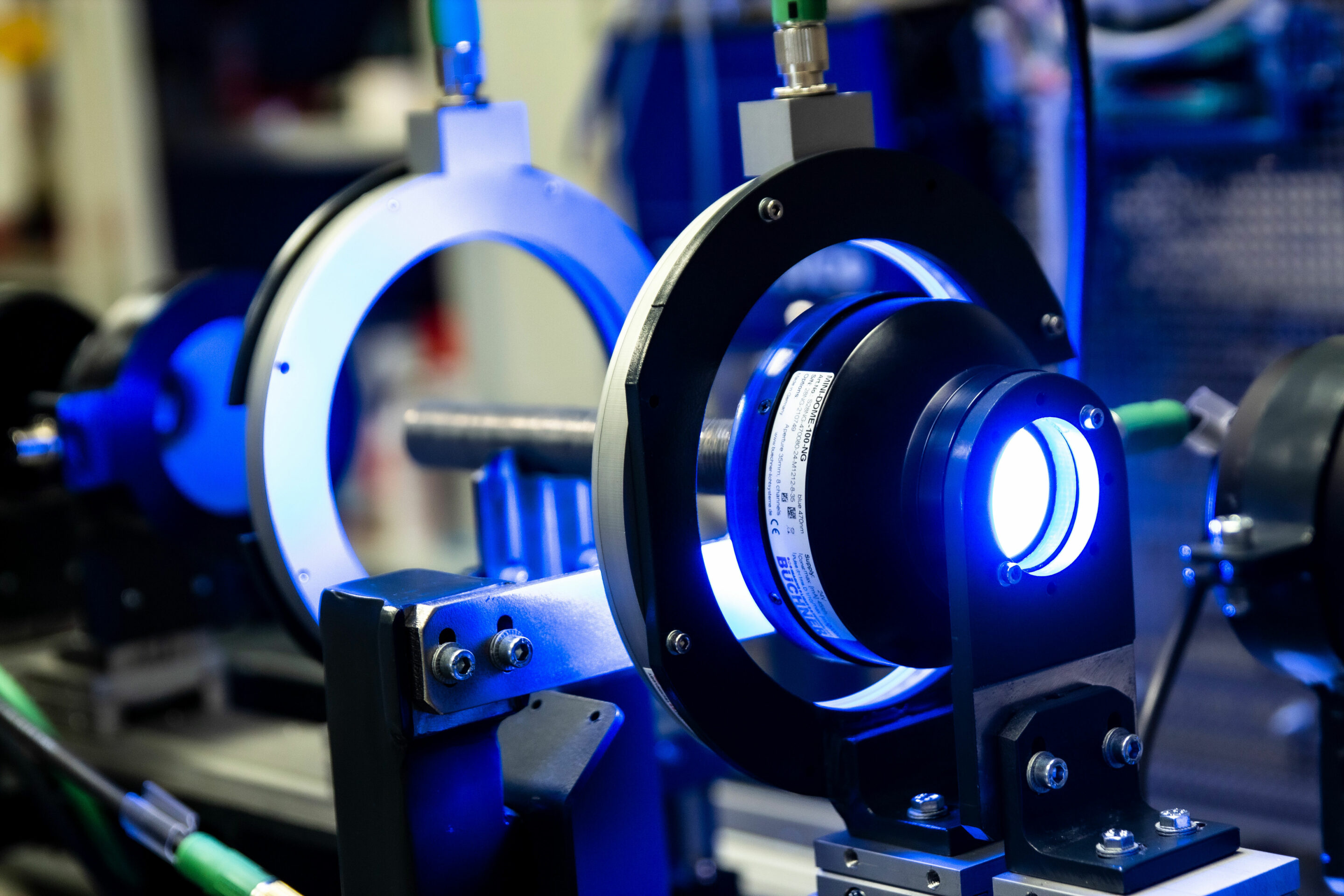

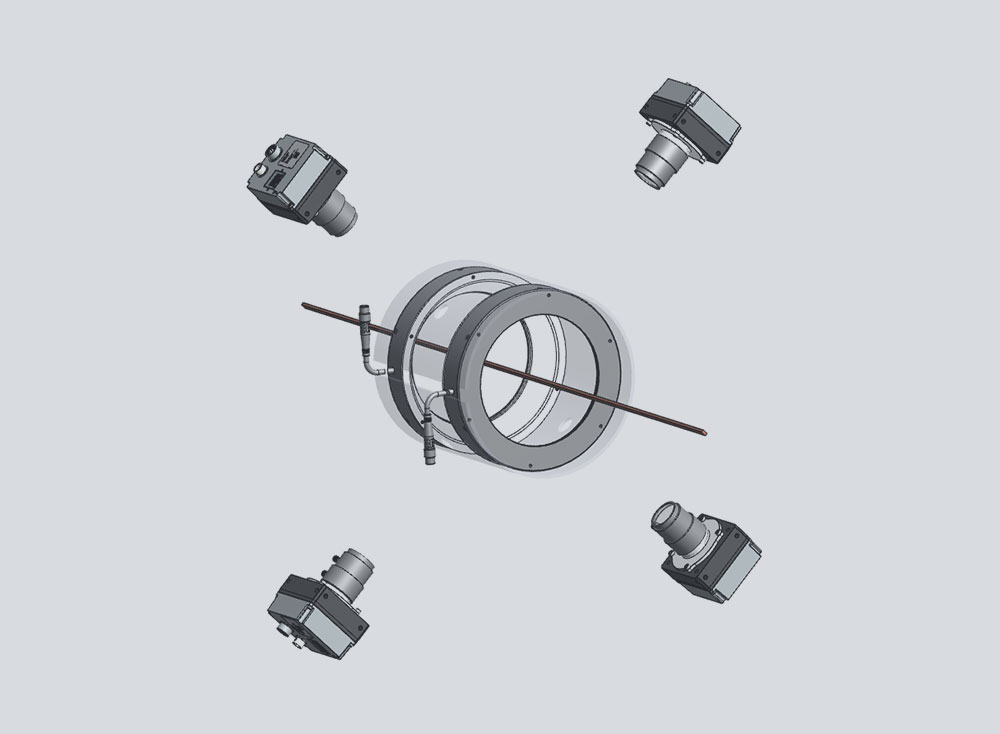

Machine vision systems from aku.automation GmbH have a modular design.

Existing solutions can be easily scaled and extended. They form the basis for customized solutions. In particular, full flexibility in the choice of imaging sensor technology allows you to implement the best and most reliable application on the market. Talk to us – our consultants will be happy to answer your questions.