Case studies

Automated matching system quality assurance in additive manufacturing

Plastic

MeasurementQuality controlType identification

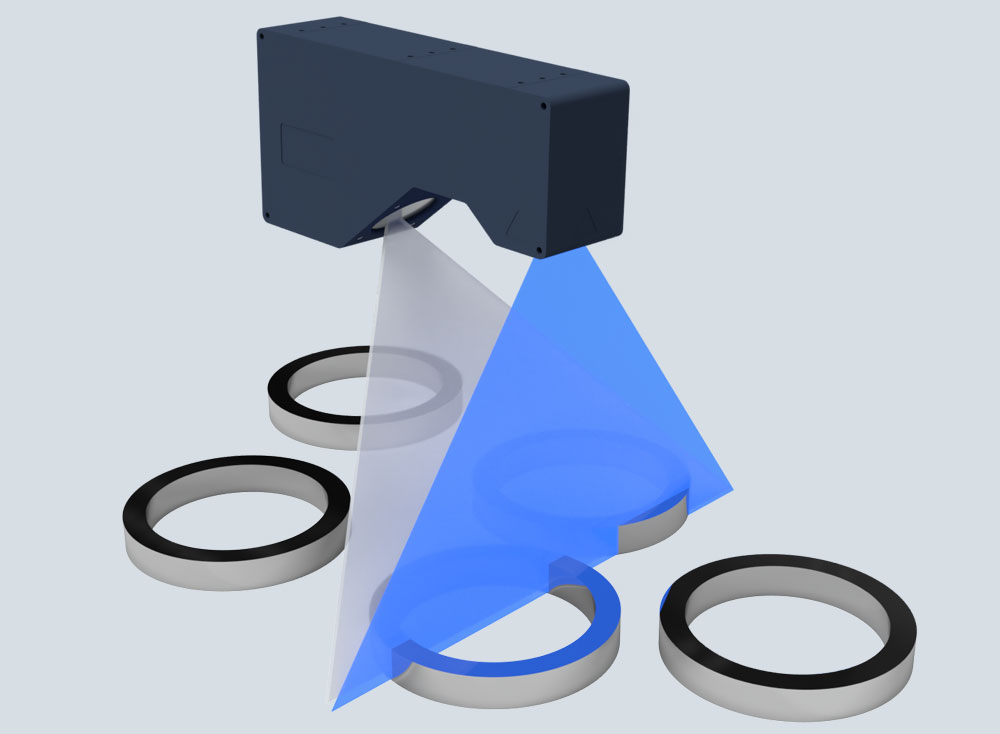

Structured light

Initial situation

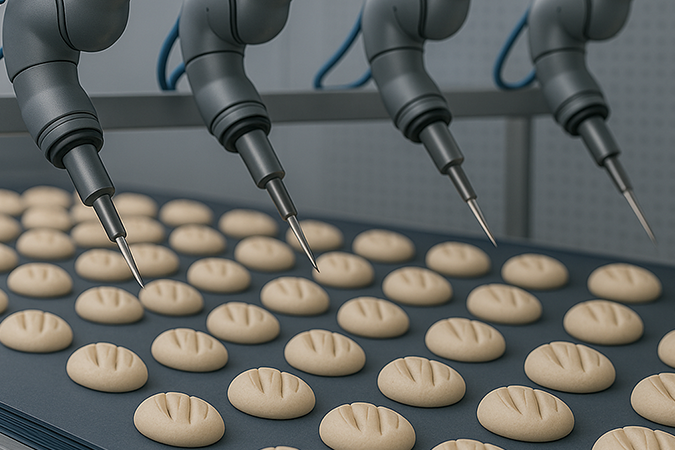

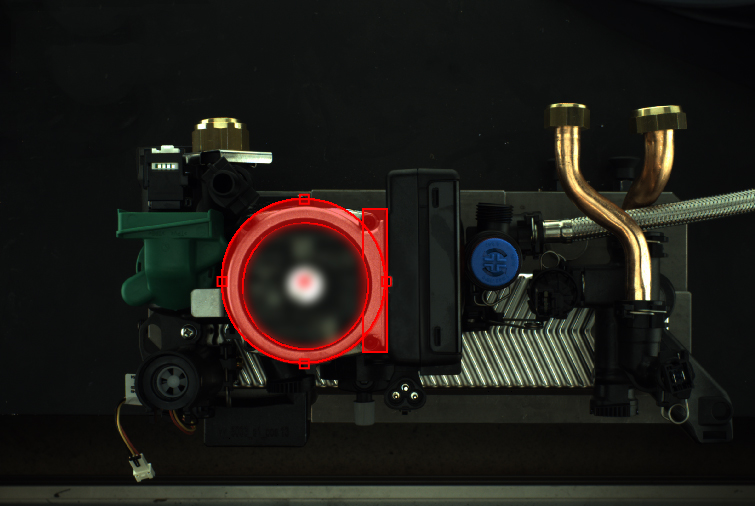

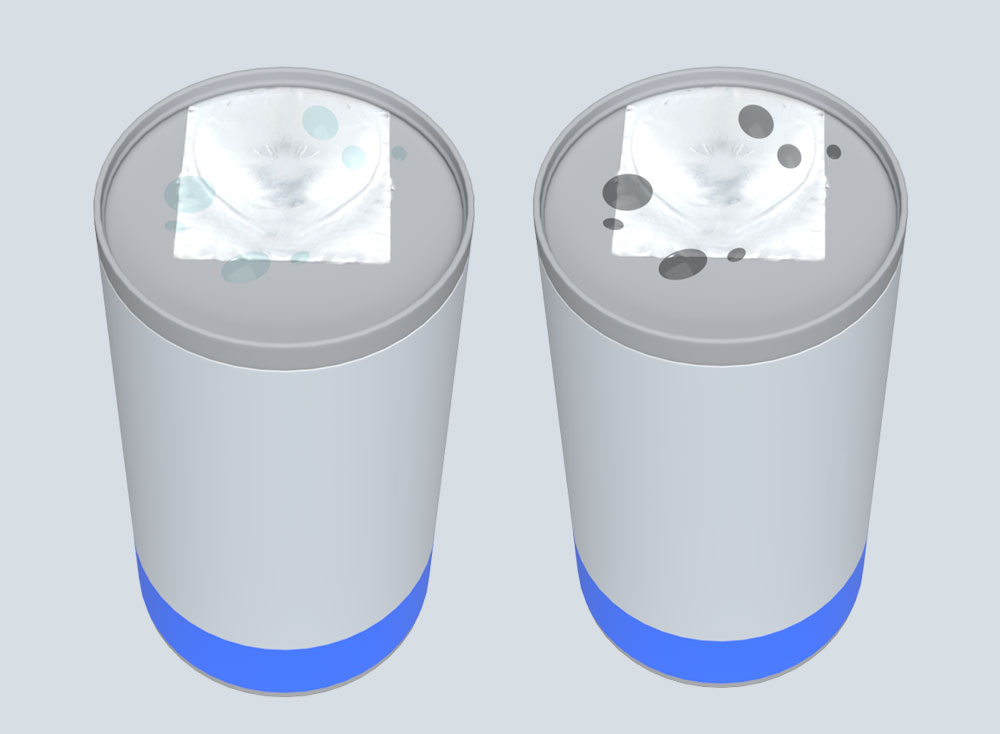

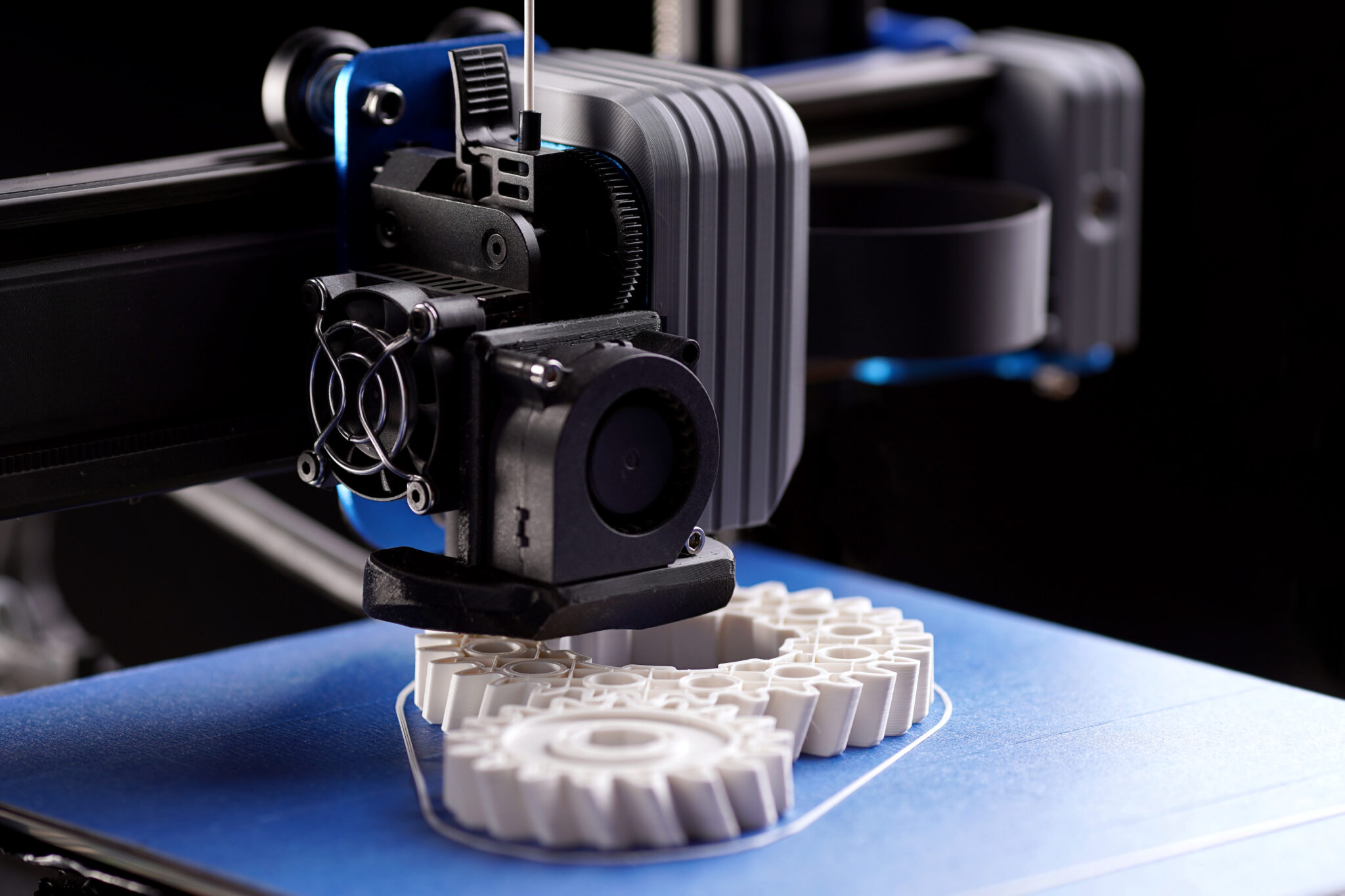

In the additive manufacturing industry, traceability plays a crucial role in quality assurance and the traceability of production processes. The use of a large number of 3D printers in particular, which produce flexible quantities ranging from individual items to several hundred units, creates an enormous pool of data. In this context, the implementation of an automated matching process for parts allocation is of great benefit in order to manage the data efficiently and optimize the production processes.

Implementation

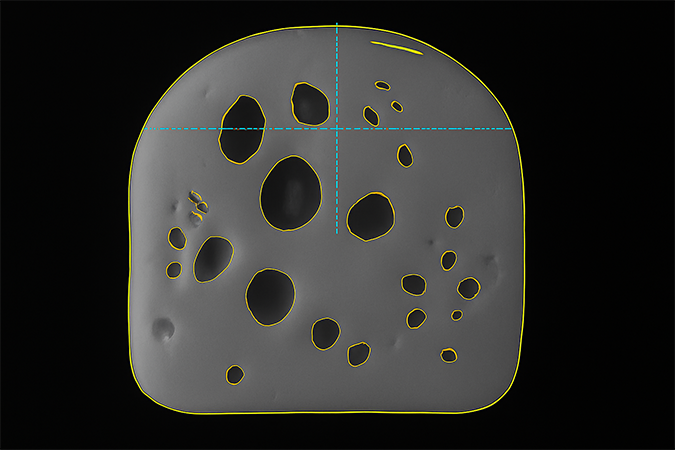

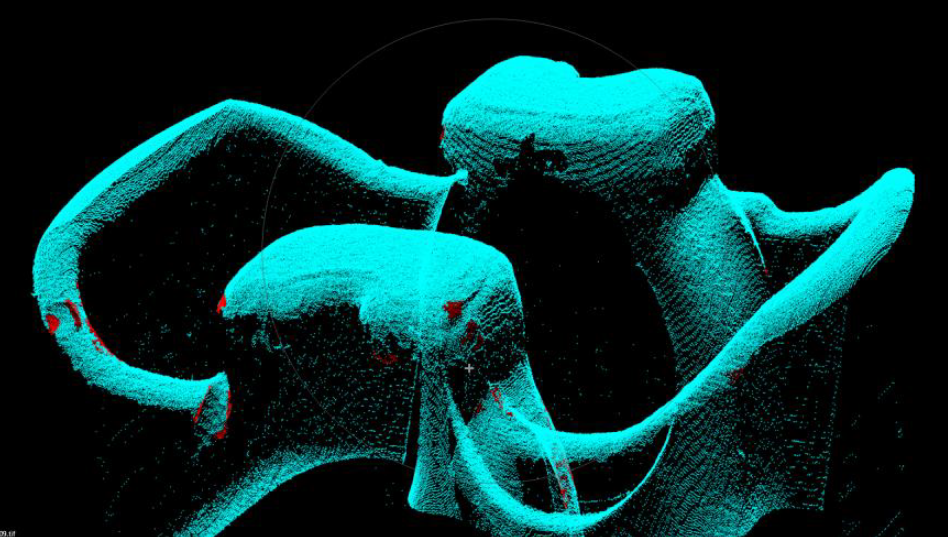

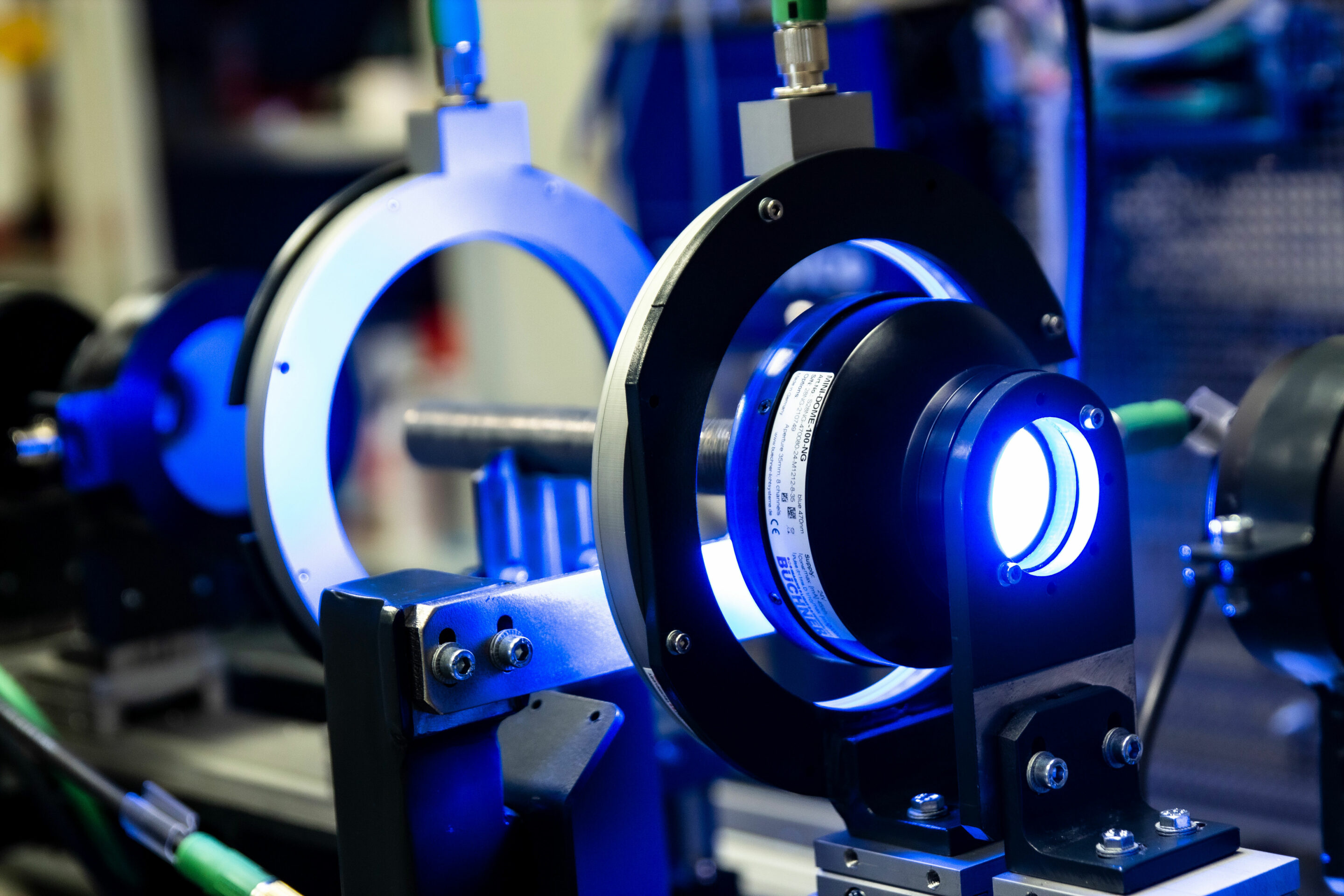

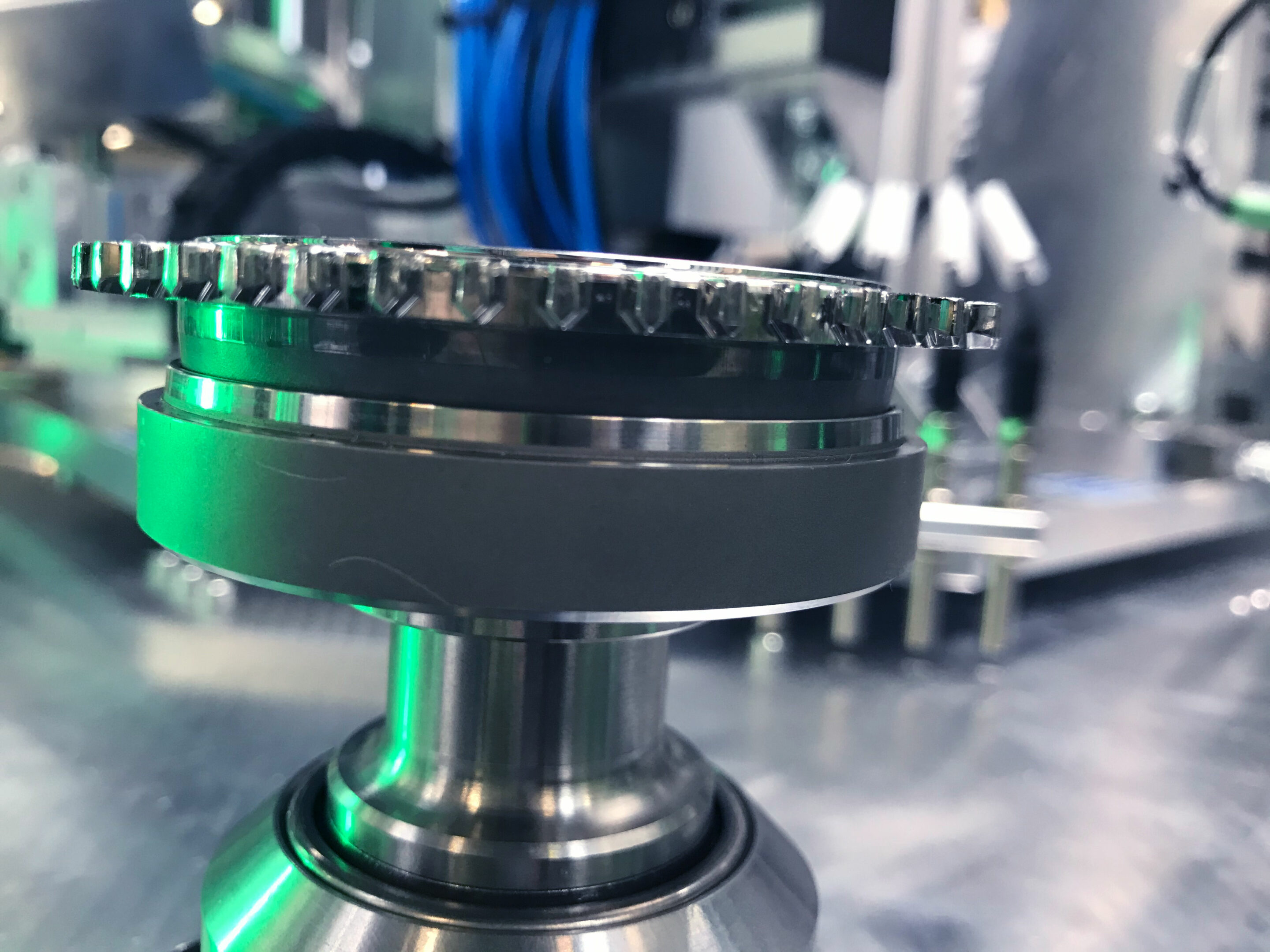

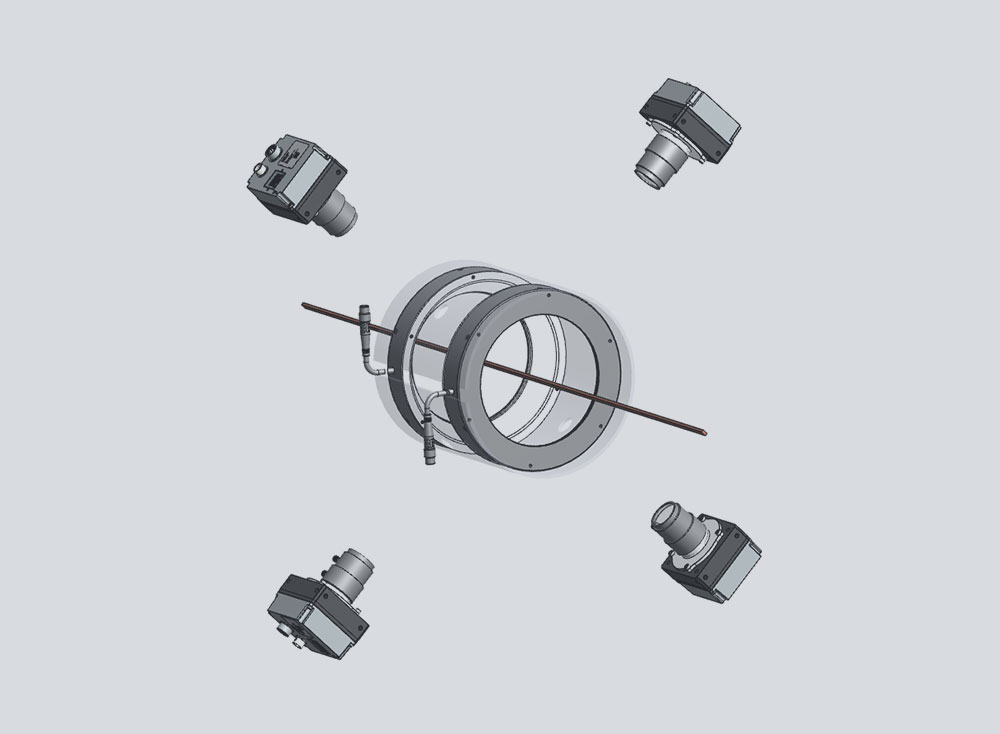

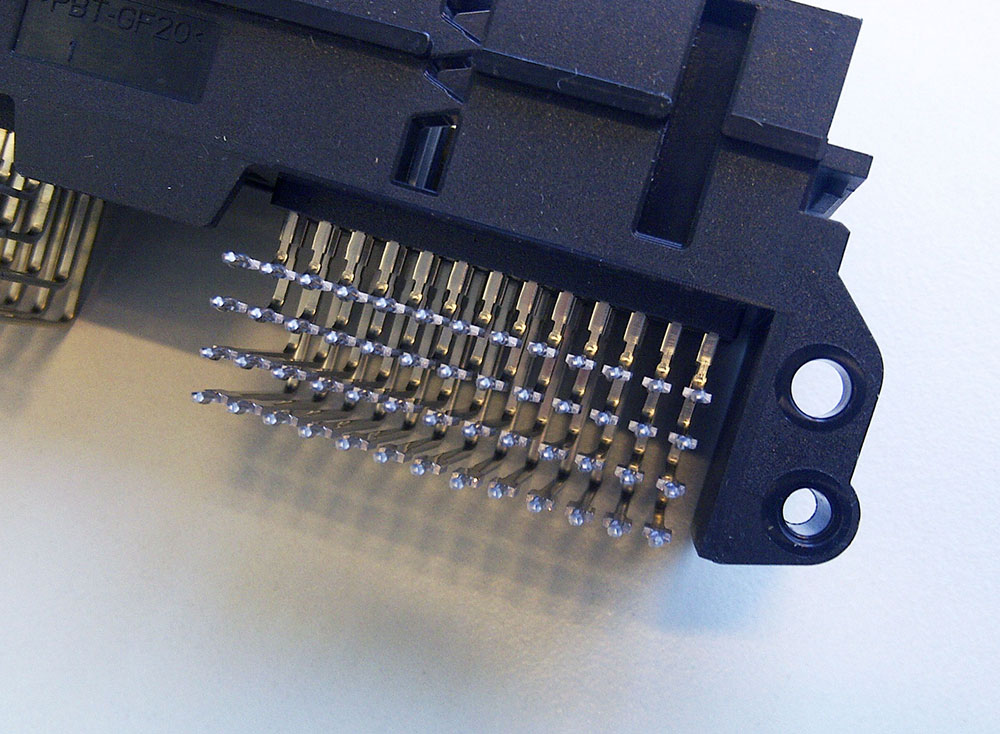

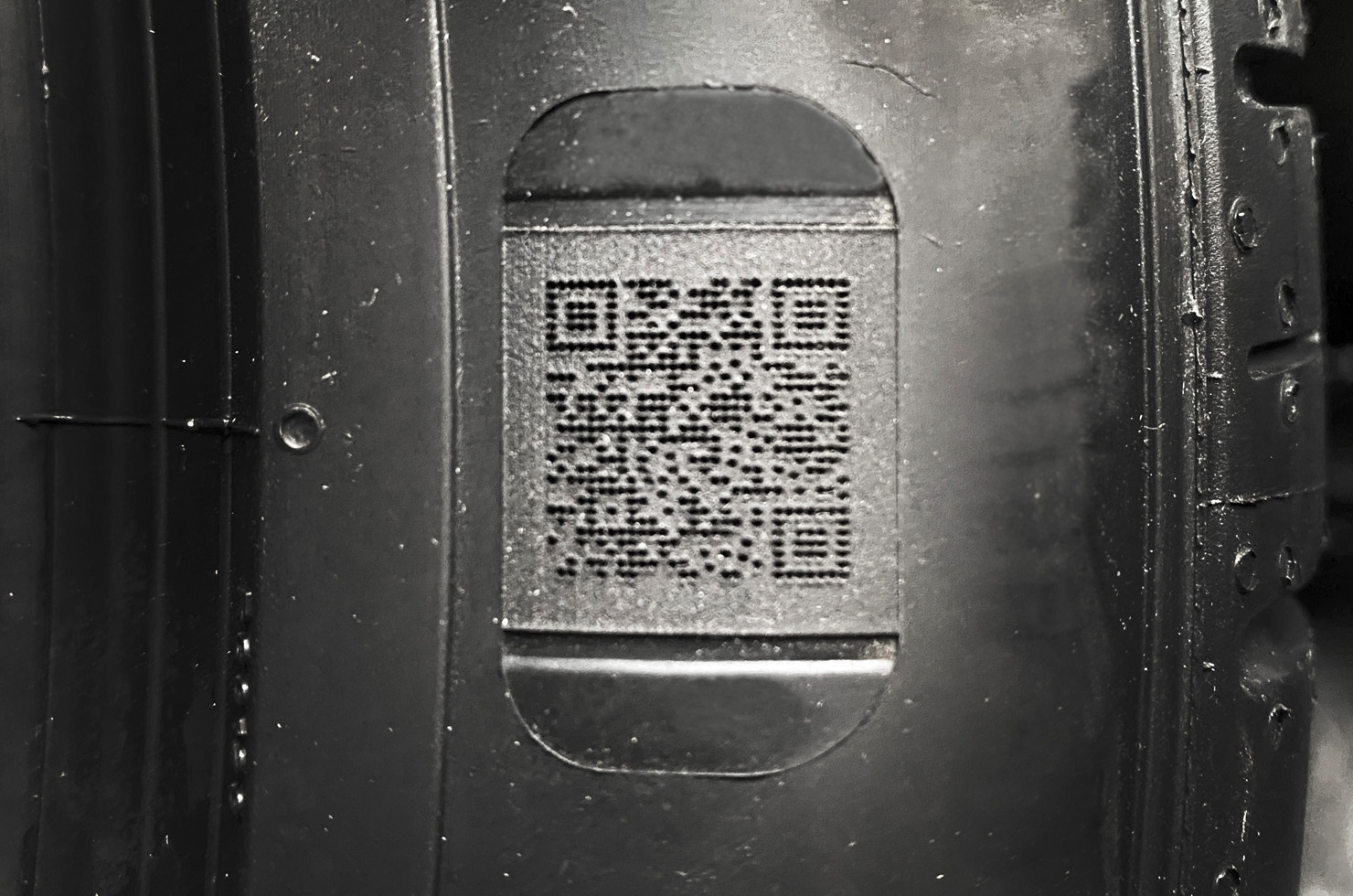

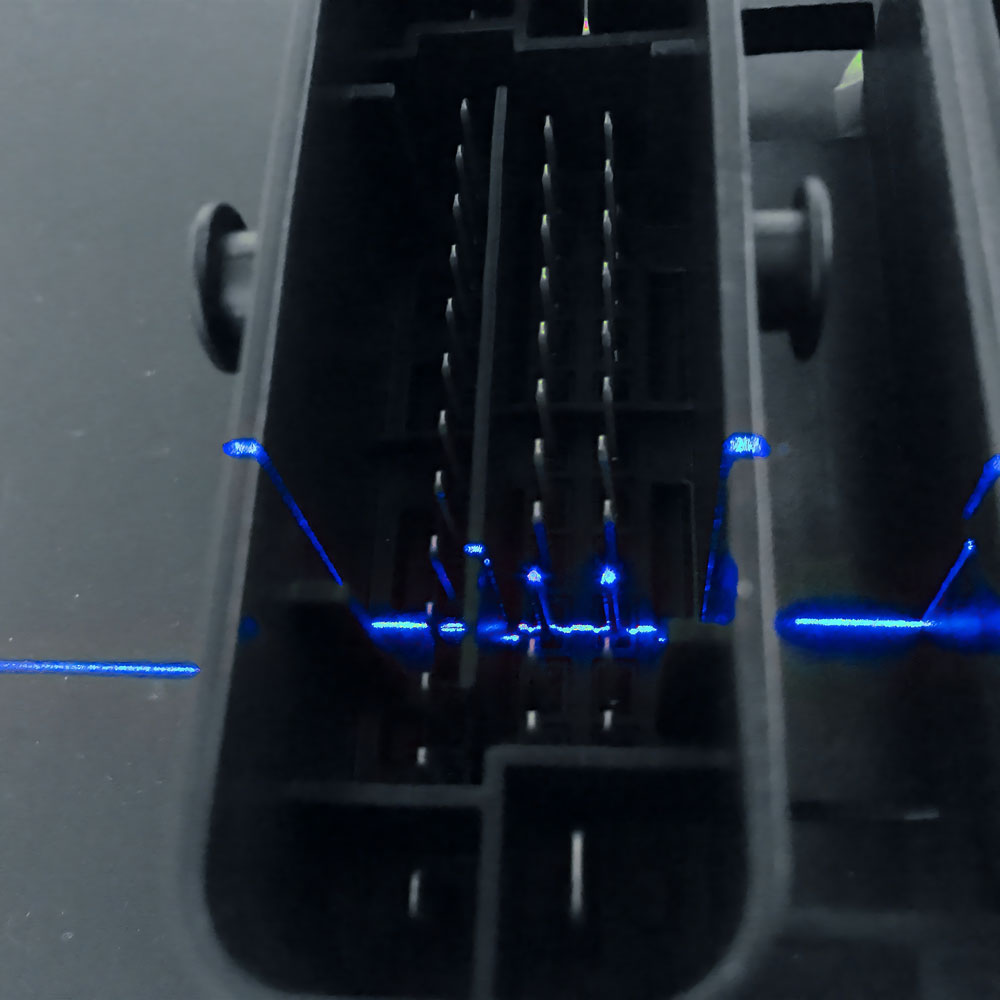

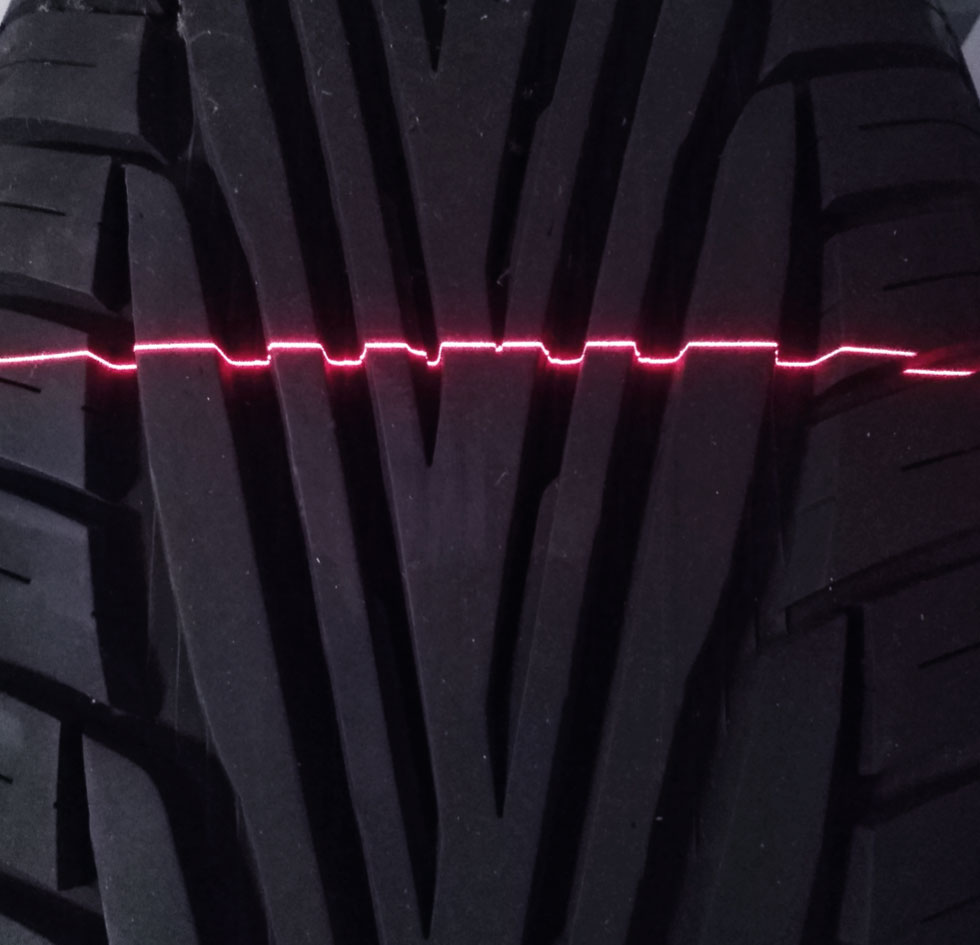

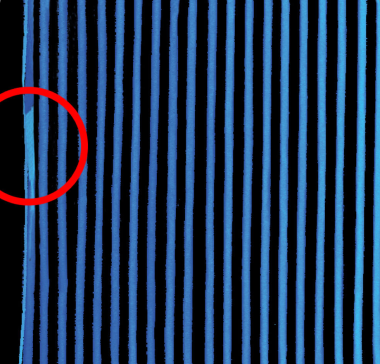

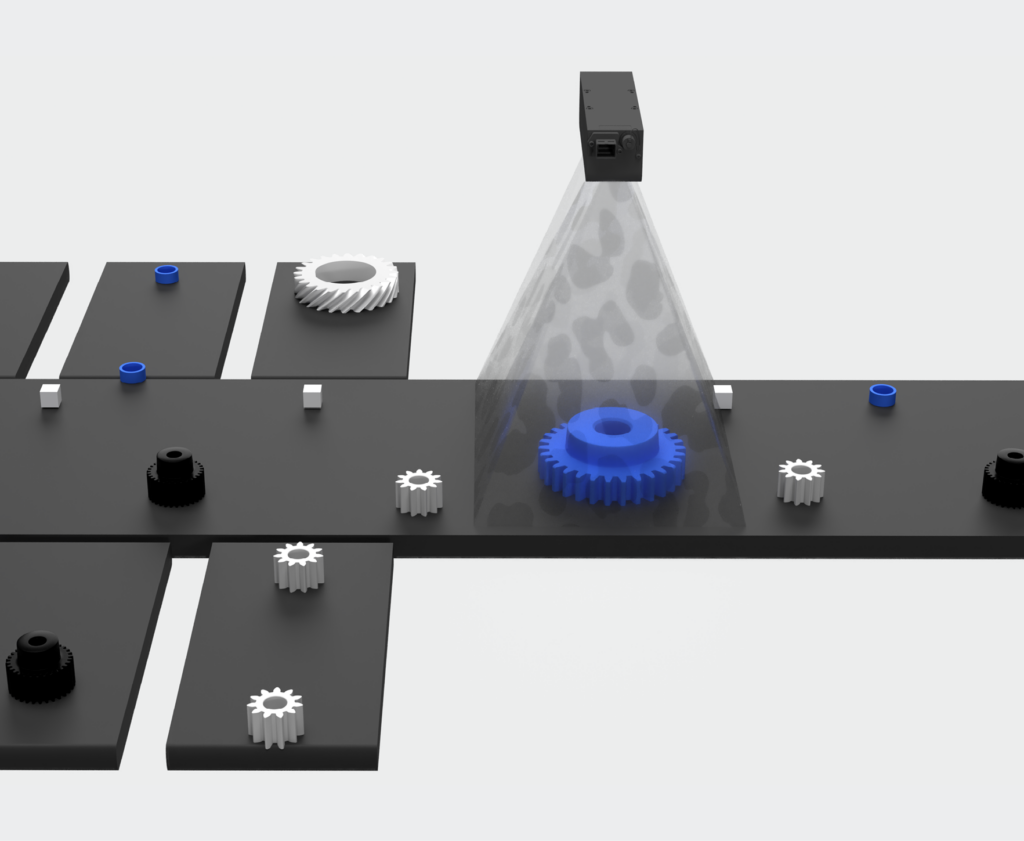

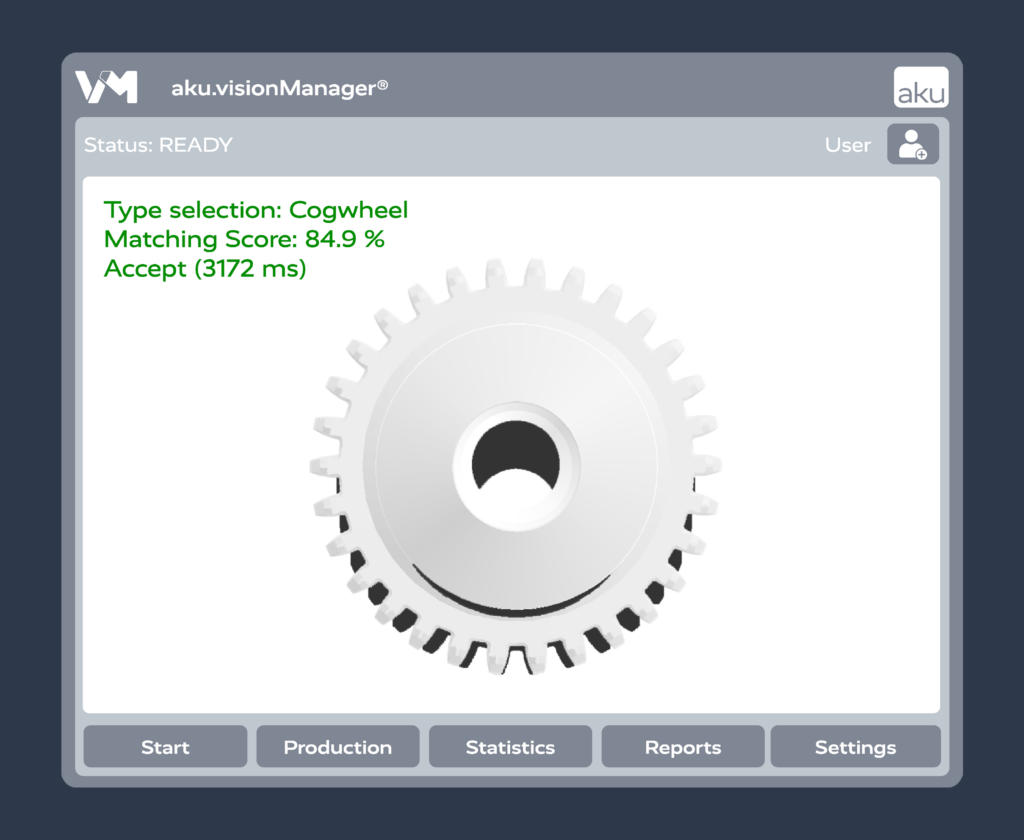

A 3D point cloud is generated with the help of a stripe light projector. A comparison is then made with the CAD model provided by the customer, which ensures reliable identification of the components. Furthermore, the system can pre-filter a large number of different 3D printed parts based on various parameters such as dimensions, surface reflection behavior, number of holes, etc. in order to save process time. In addition, the system can measure the part using the 3D data and check defined test surfaces for dimensional accuracy. The evaluation is based on the aku.visionManager® software. Communication between the system and the 3D printer takes place via a TCP/IP interface. The system can also communicate with the higher-level PLC controller via the Profinet protocol.

Parameters

- Anomaly adjustment

- Test time: 2-8 seconds per part

- Variable working range: 20 – 1000 mm (depending on part size)

Customer benefits

The machine vision system and aku.visionManager® software enable time- and cost-saving inspection. Thanks to its flexibility, sorted data processing and modularity, the system is able to make traceability transparent for the customer. This increases productivity and enables components to be measured immediately after production, which sets the customer apart from the competition.

Your contact person

Christian Merten

Head of Sales

Email: c.merten@aku.eu

Phone: +49 151 / 259 190 10

Case studies

You might also be interested in:

Machine vision systems from aku.automation GmbH have a modular design.

Existing solutions can be easily scaled and extended. They form the basis for customized solutions. In particular, full flexibility in the choice of imaging sensor technology allows you to implement the best and most reliable application on the market. Talk to us – our consultants will be happy to answer your questions.