Case studies

Discover impressive case studies that showcase aku’s successes and innovations in various industries.

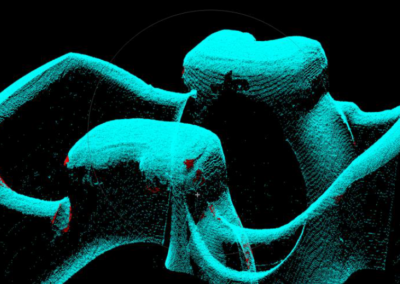

Sealing seam inspection for cheese packaging with thermoforming trays

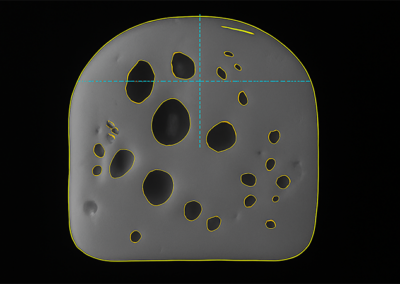

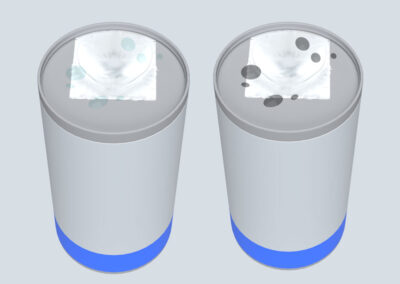

Sectional image inspection of cheese slices

AI-supported surface inspection and measurement of aluminum ingots

Fault-free pistons: precise 3D inspection in the rotary indexing system

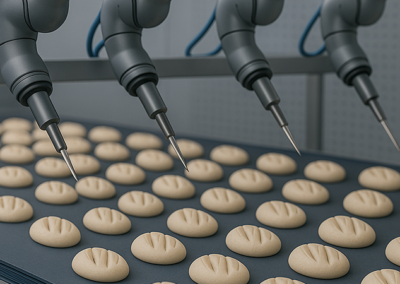

Reliable foreign object detection in food production

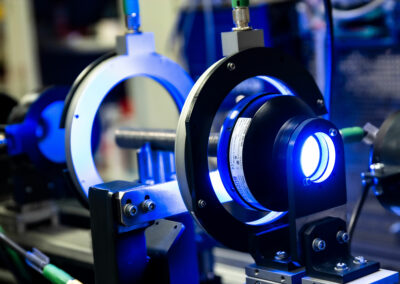

Optical measurement for precise quality control of tubes and round bars

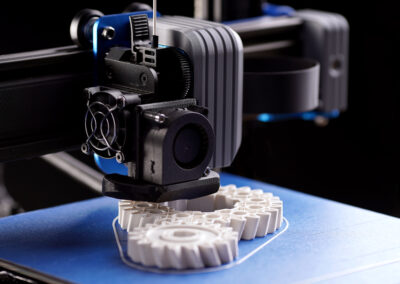

Automated matching system quality assurance in additive manufacturing

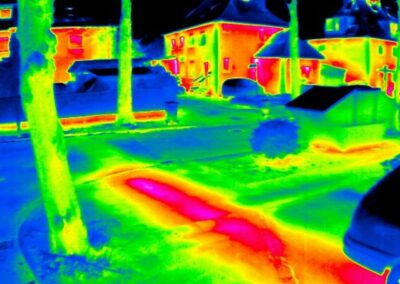

Innovative inspection of district heating networks with artificial intelligence

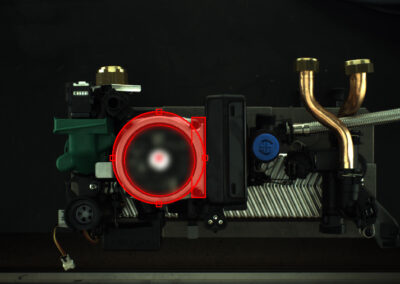

AI-supported installation control of heat pumps

From target/actual comparison to AI-controlled circuit board inspection

100-percent control of sealed seams

2D and 3D inspection of batteries

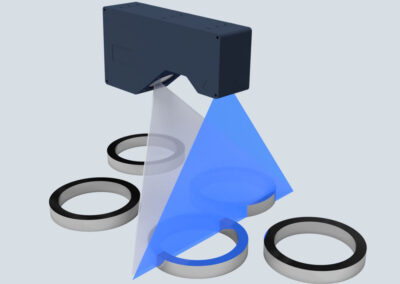

3D position determination of metal rings

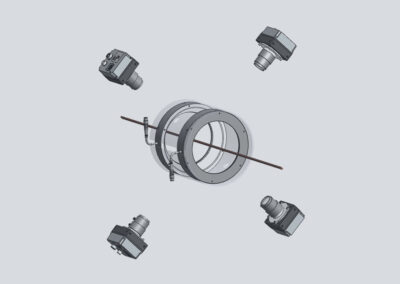

Automated final inspection of coupling bodies

Check for intactness and completeness of cardboard boxes

Checking of best before date, EAN and type number on labels

Efficient identification of batch numbers in the cosmetics industry

Efficient parcel logistics: machine vision for fast deliveries

Measurement Hairpin

Position determination and shape control of packaging

Precise logistics: intelligent loading for smooth deliveries

Quality improvement in the production of heated windscreens

Swing stopper and rubber seal inspection on bottles

Temperature control of casting moulds

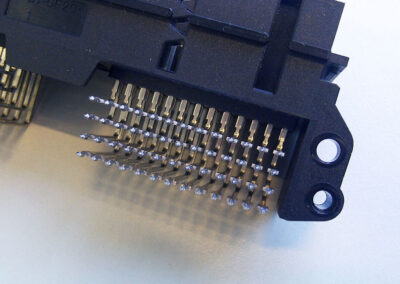

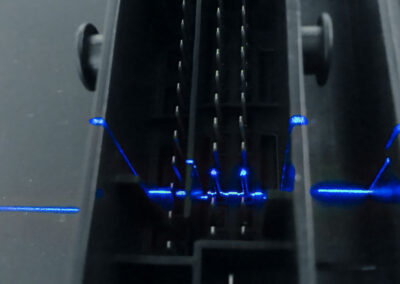

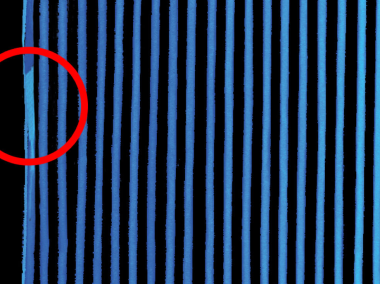

Tumbling circle inspection on plug connections

Weld bead control on electric motors

Detection of barcodes, QR codes, DOT codes and color points

3D height and tumbling circle inspection on plug connections

Character recognition (OCR) using Shape from Shading

Determination of manufacturer, size and tread depth on tires

Quality control of cabin air filters for passenger cars