Case studies

Measurement Hairpin

Automotive

MeasurementPosition controlSurface inspection

Telecentricity 2D technology Line scan camera

Initial situation

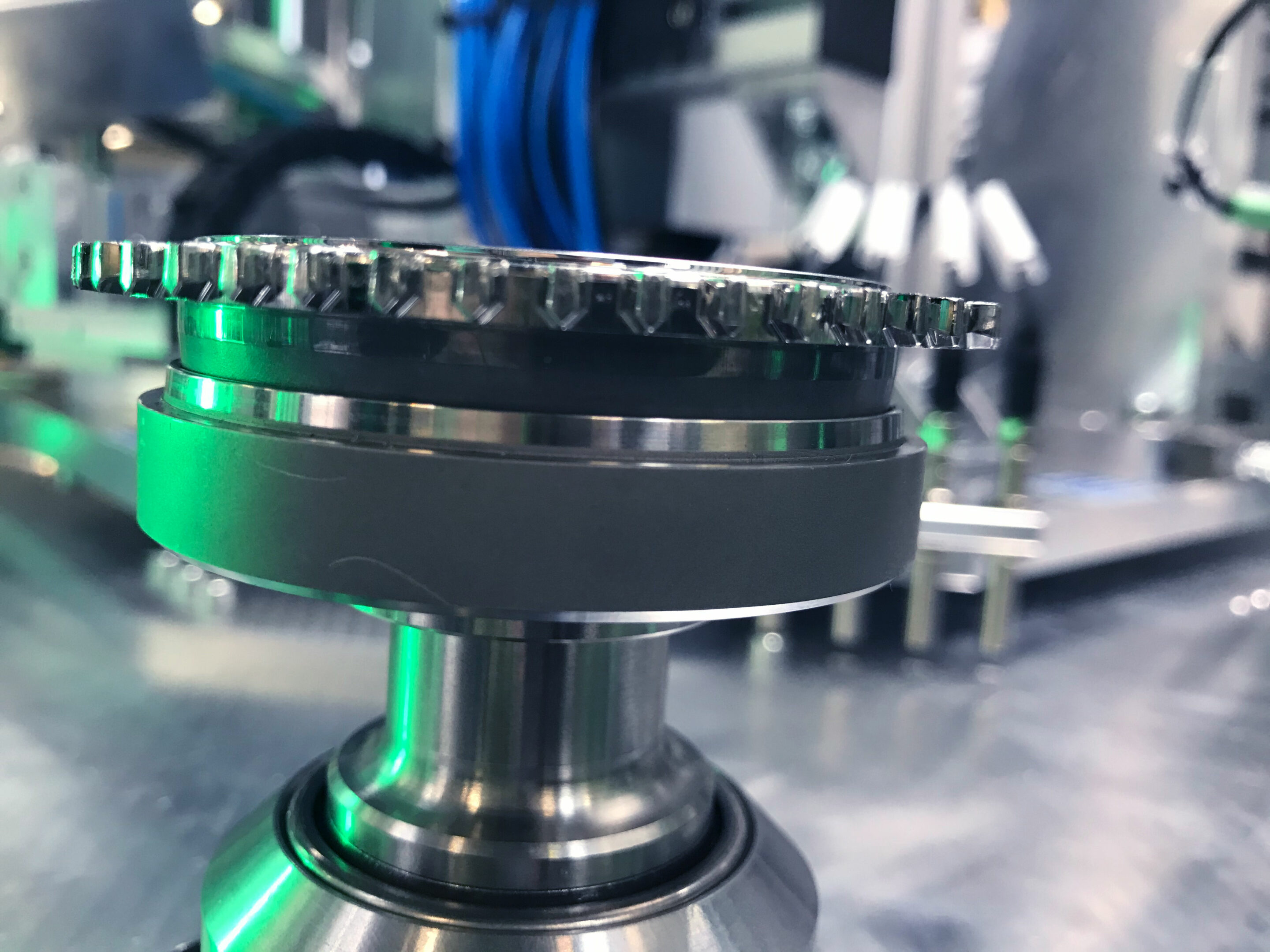

In the field of e-mobility, the hairpin process has become established in the development of e-motors and the associated production. Here, copper wires, similar to a hairpin, are inserted into the grooves of the stator and welded. In the production of the individual hairpins, the copper wire passes through the following production steps: Stripping, cutting, bending and welding. Dimensional accuracy is a basic requirement for the subsequent fully automatic assembly steps, which guarantees a smooth production process.

Implementation

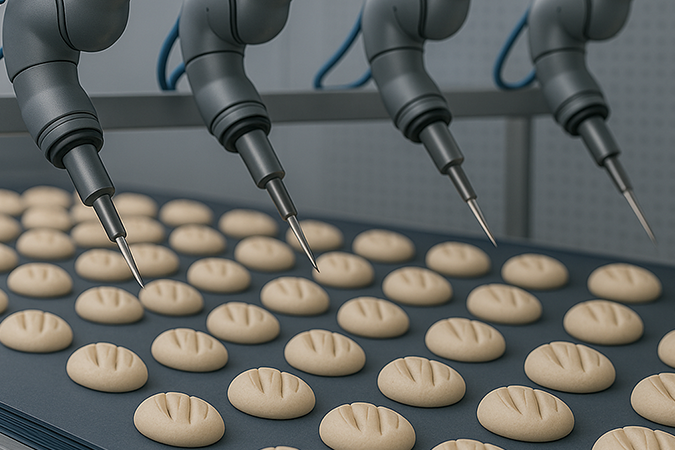

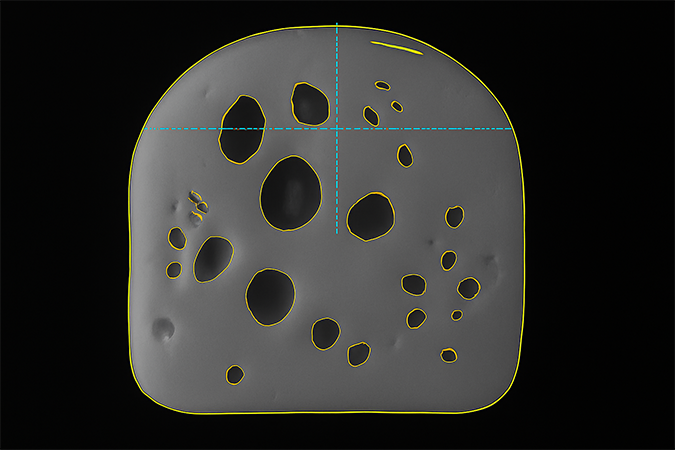

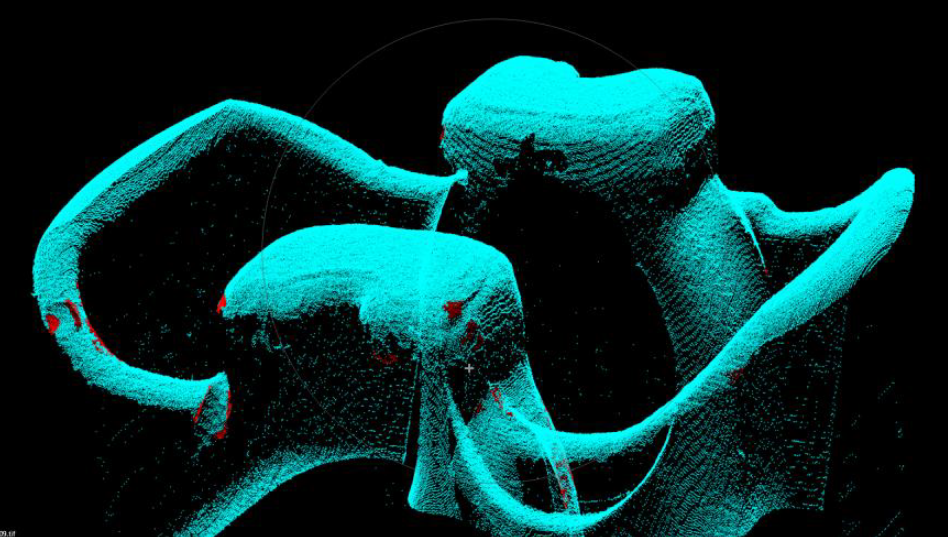

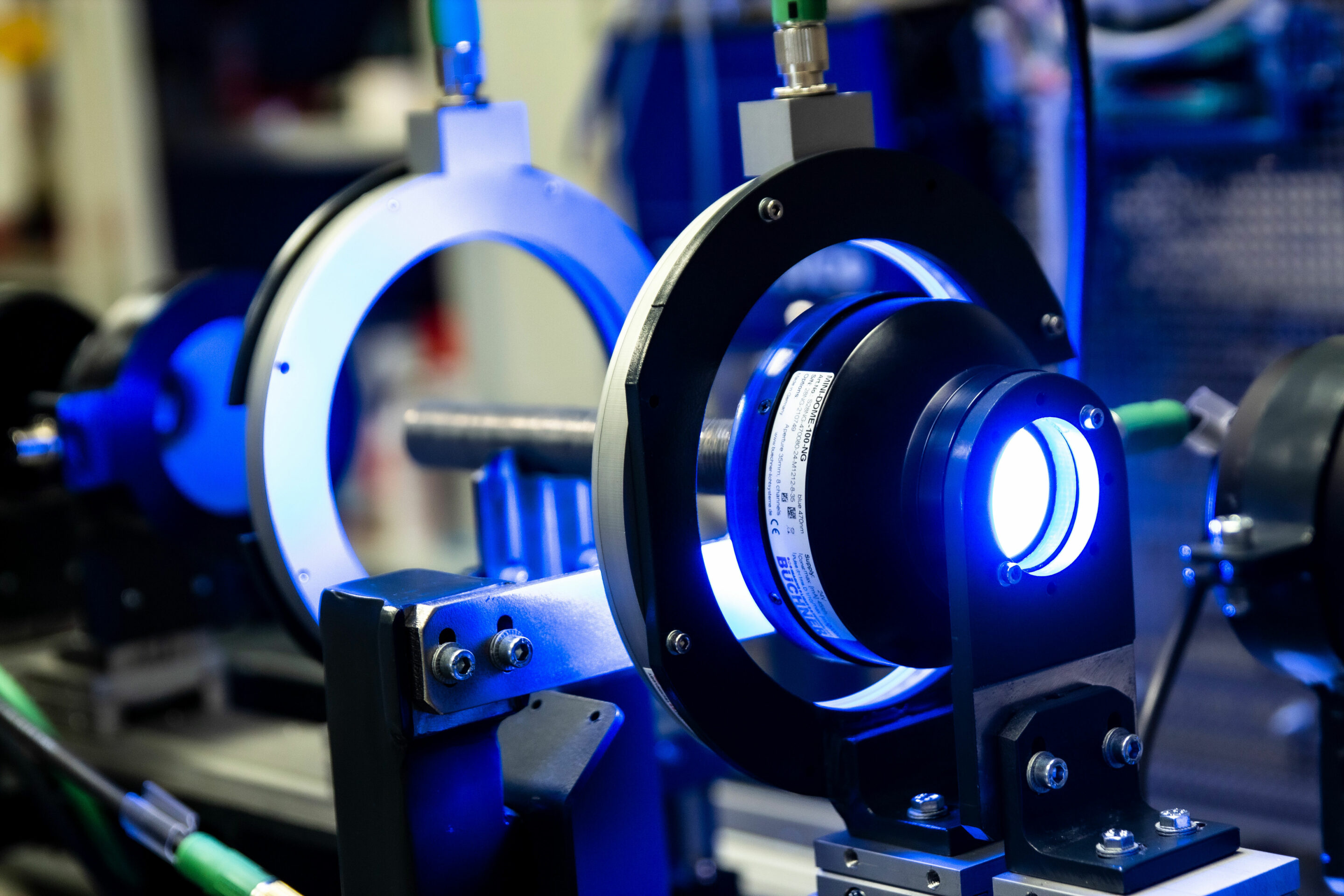

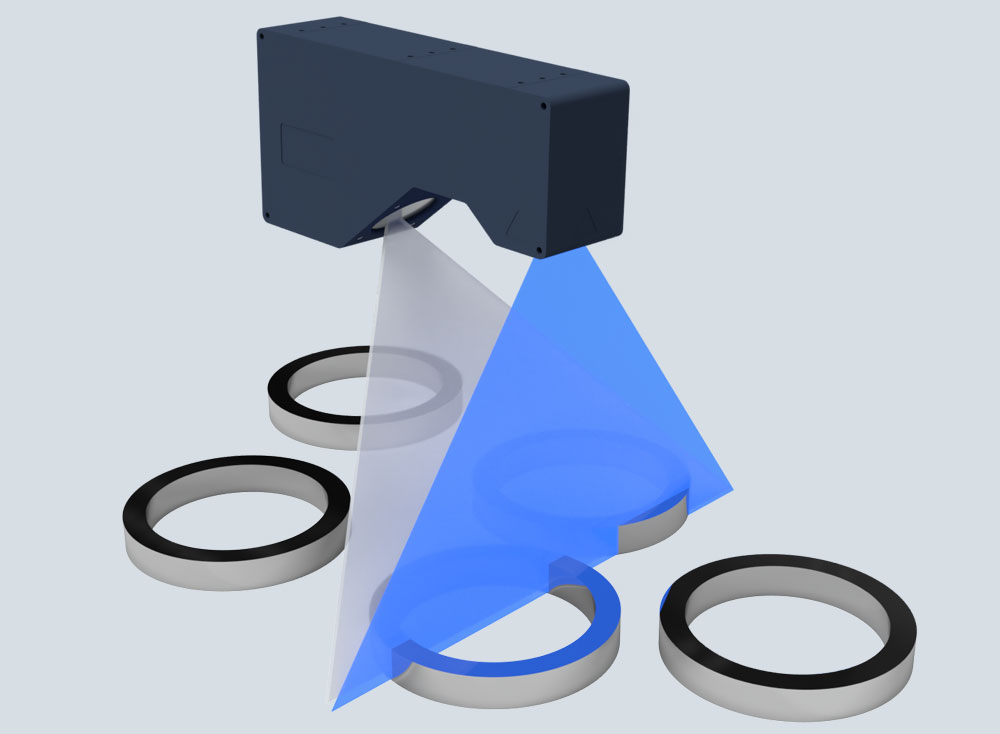

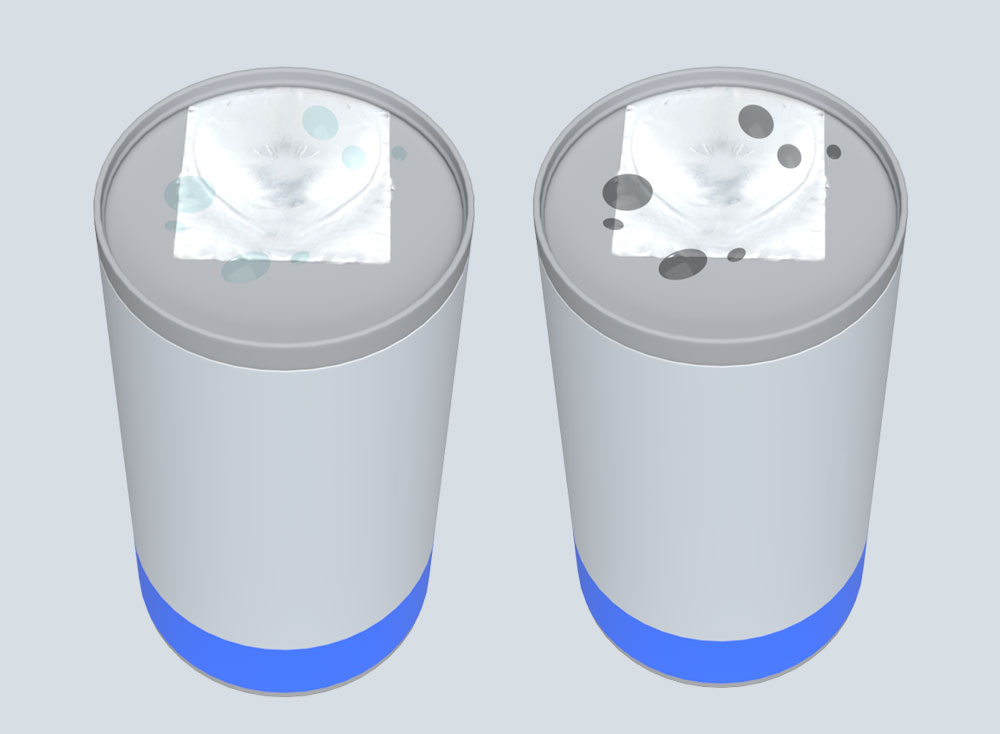

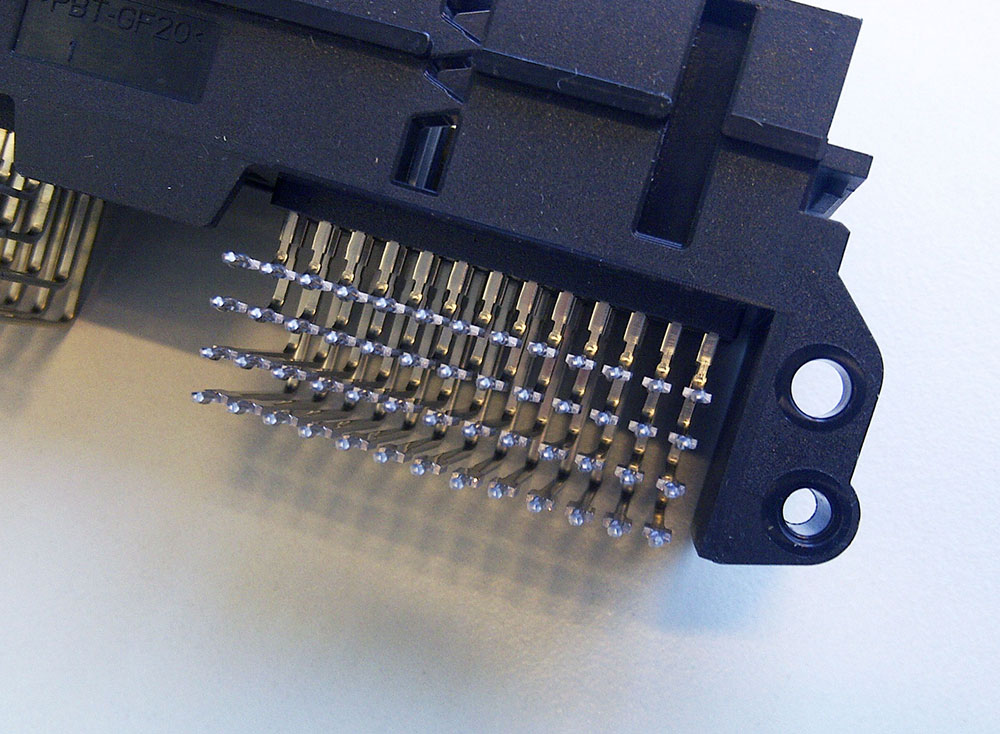

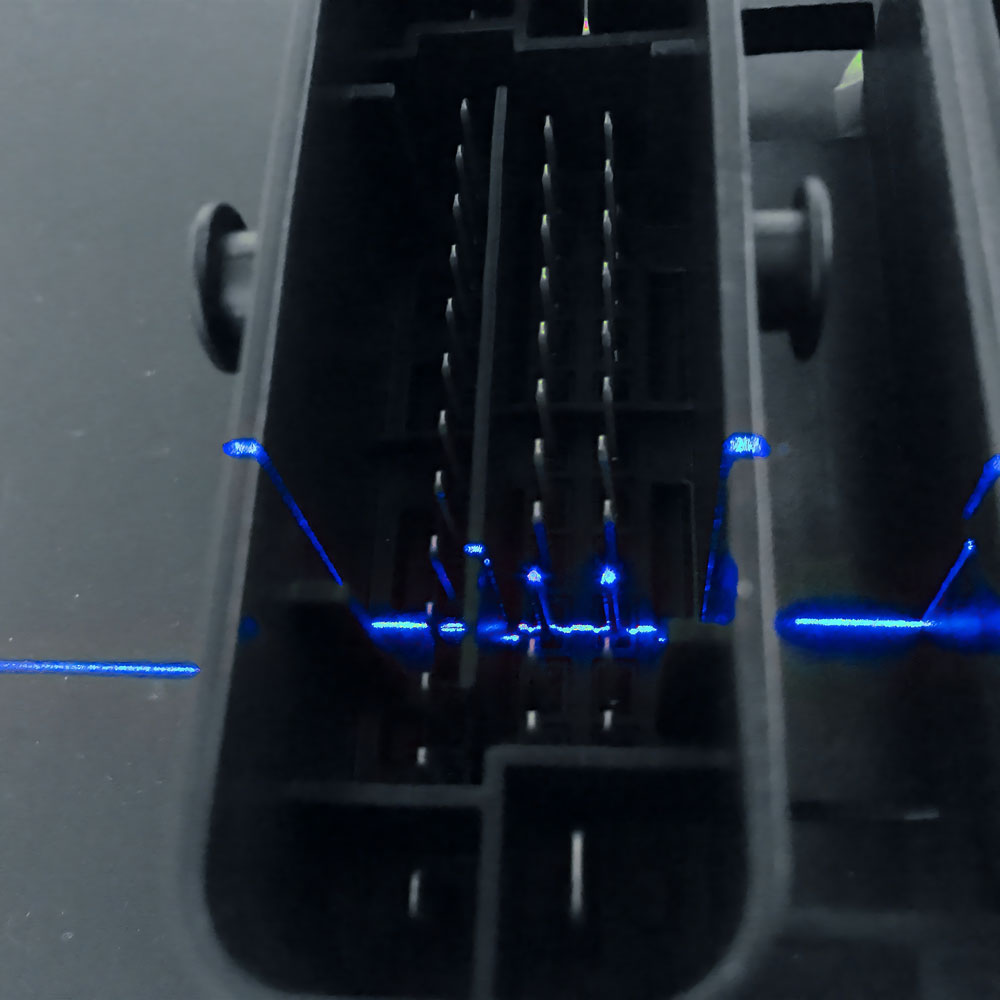

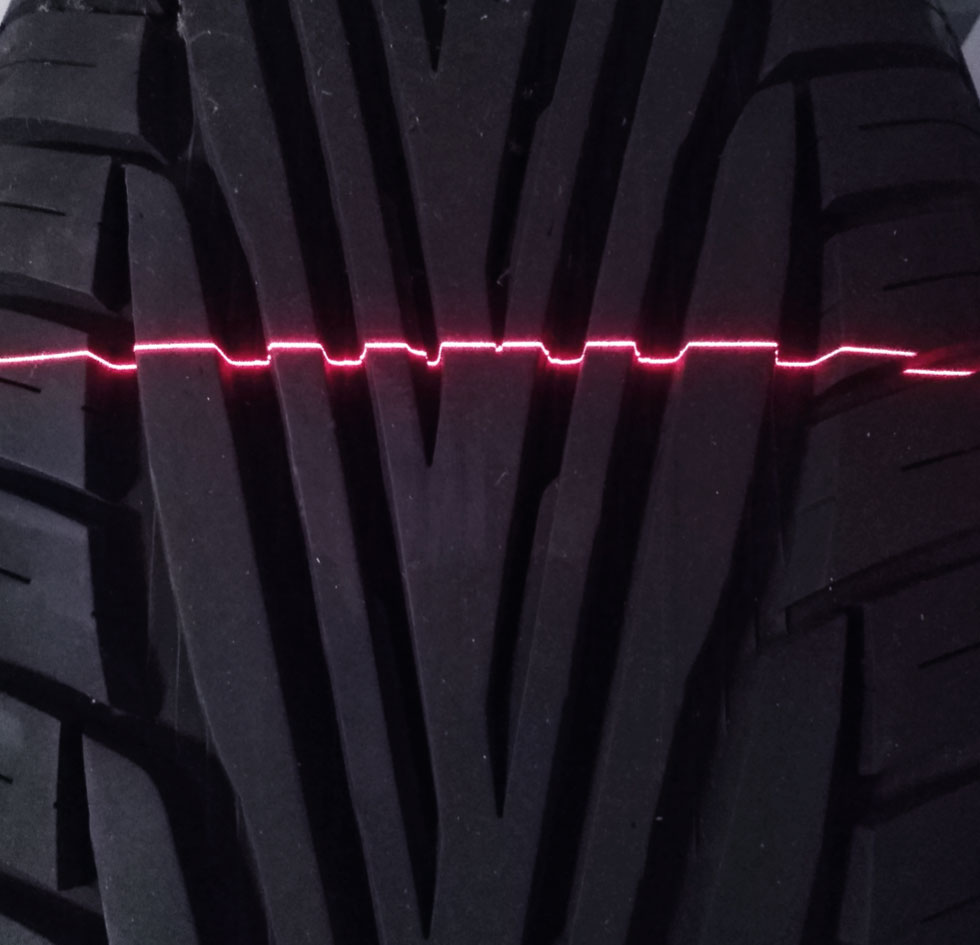

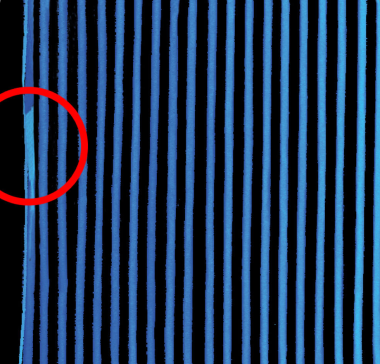

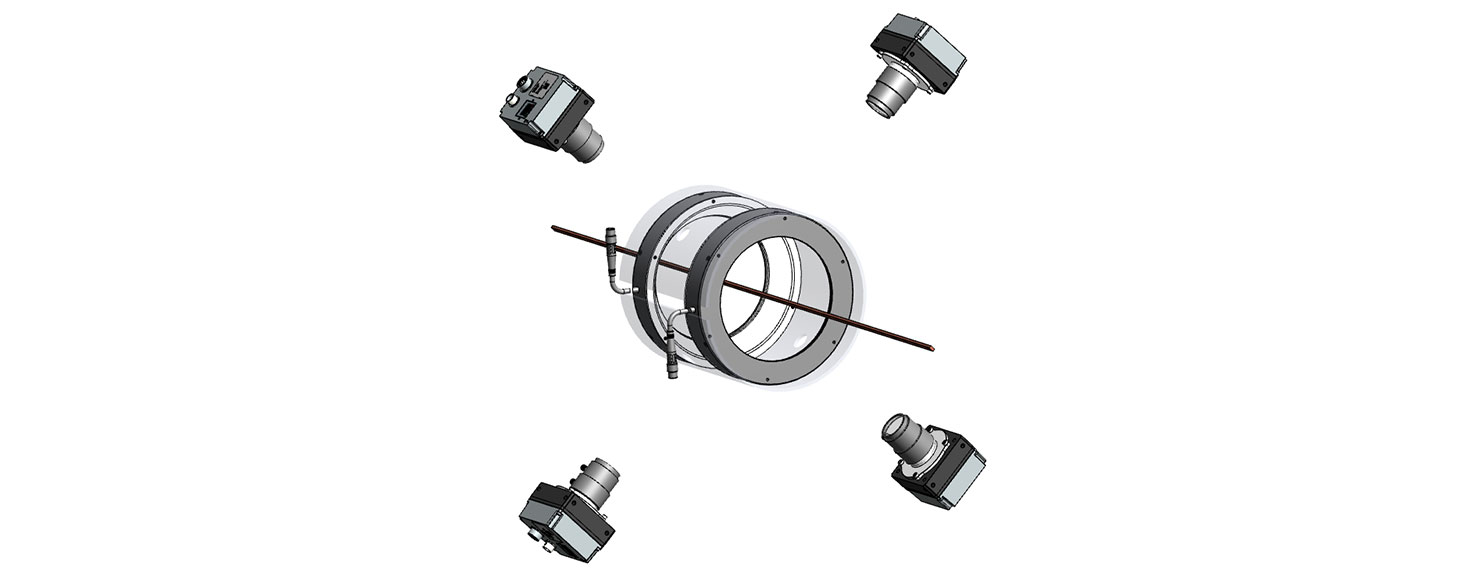

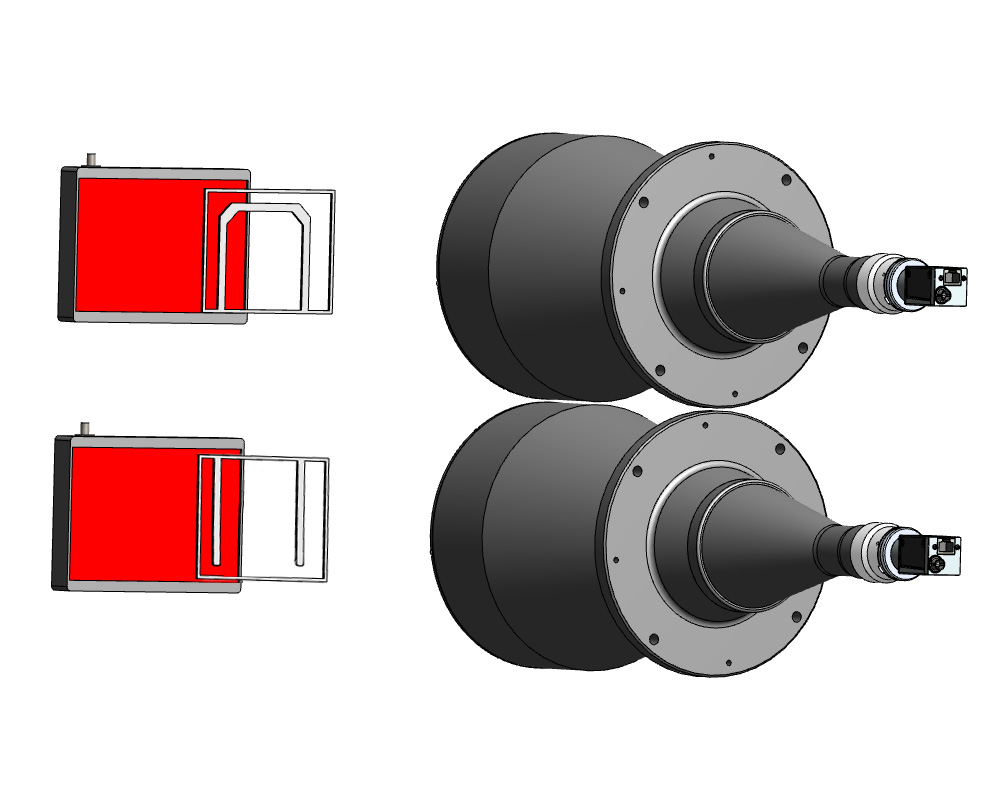

With the help of four line scan cameras a 360-degree control of the stripping process of the copper wire is carried out. For this purpose, the wire is transported centrally through the LED illumination unit and the cameras. There must be no residues of the insulation coating on the surface of the wire. In the subsequent bending process, the hairpin is measured for its dimensional accuracy using area cameras and telecentric lens in a transmitted light process. The length, parallelism and angle of the hairpins are checked. In a further test step, the torsion of both hairpin ends is measured with an area scan camera.

Parameters

- Capable of measuring

- Accuracy in 1/10mm

- Measured value logging

Customer benefits

The customer is provided with the individual measured values and parameters via the visualization of the system. The measured values are also transferred to the machine control system and thus flow directly into the production processes. If the limit value is exceeded, the corresponding hairpin is rejected. The measured values that lie within the tolerance are also available to the machine control system as control variables. Thus, the NOK portion of hairpins can be minimized and the process can be optimally designed. The effectiveness of the machine is significantly increased by this control process.

Your contact person

Christian Merten

Head of Sales

Email: c.merten@aku.eu

Phone: +49 151 / 259 190 10

Case studies

You might also be interested in:

Machine vision systems from aku.automation GmbH have a modular design.

Existing solutions can be easily scaled and extended. They form the basis for customized solutions. In particular, full flexibility in the choice of imaging sensor technology allows you to implement the best and most reliable application on the market. Talk to us – our consultants will be happy to answer your questions.