Case studies

2D and 3D inspection of batteries

Consumer goodsElectronics

Quality controlSurface inspection

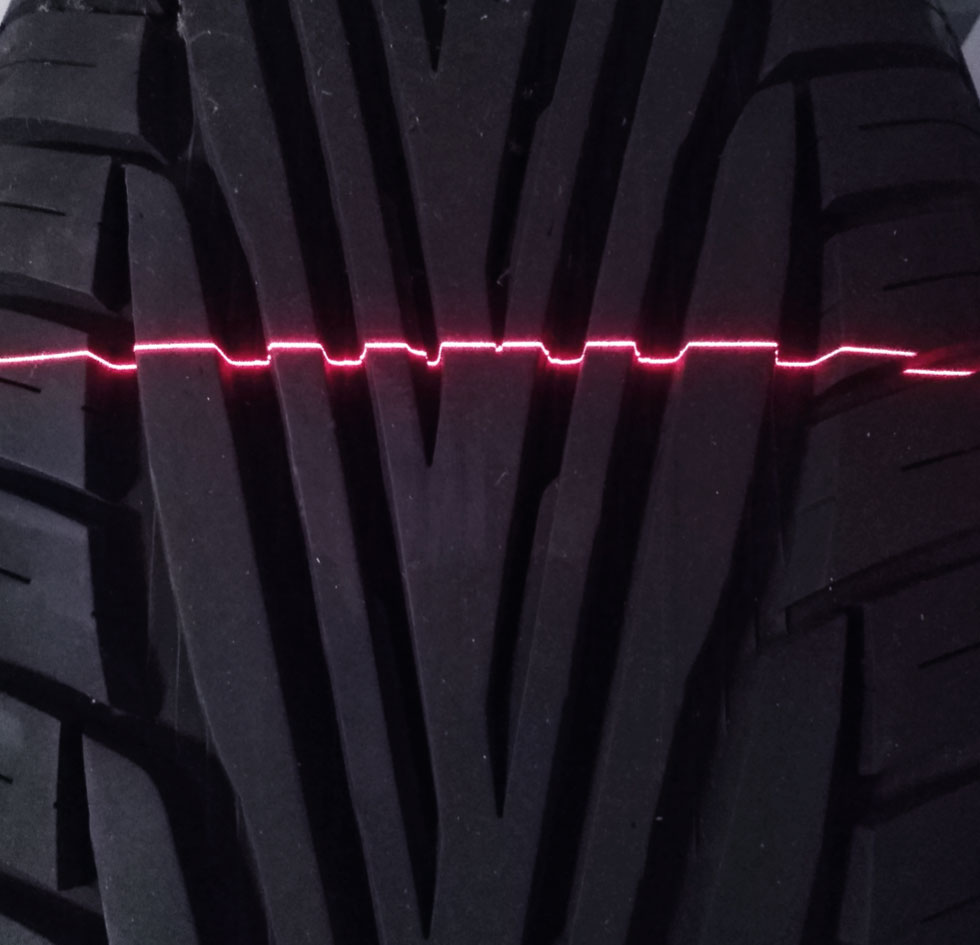

Laser triangulation 2D technology

Initial situation

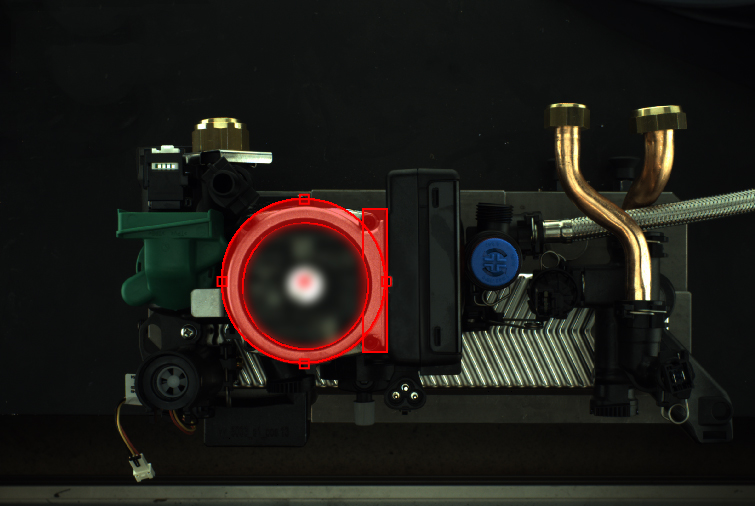

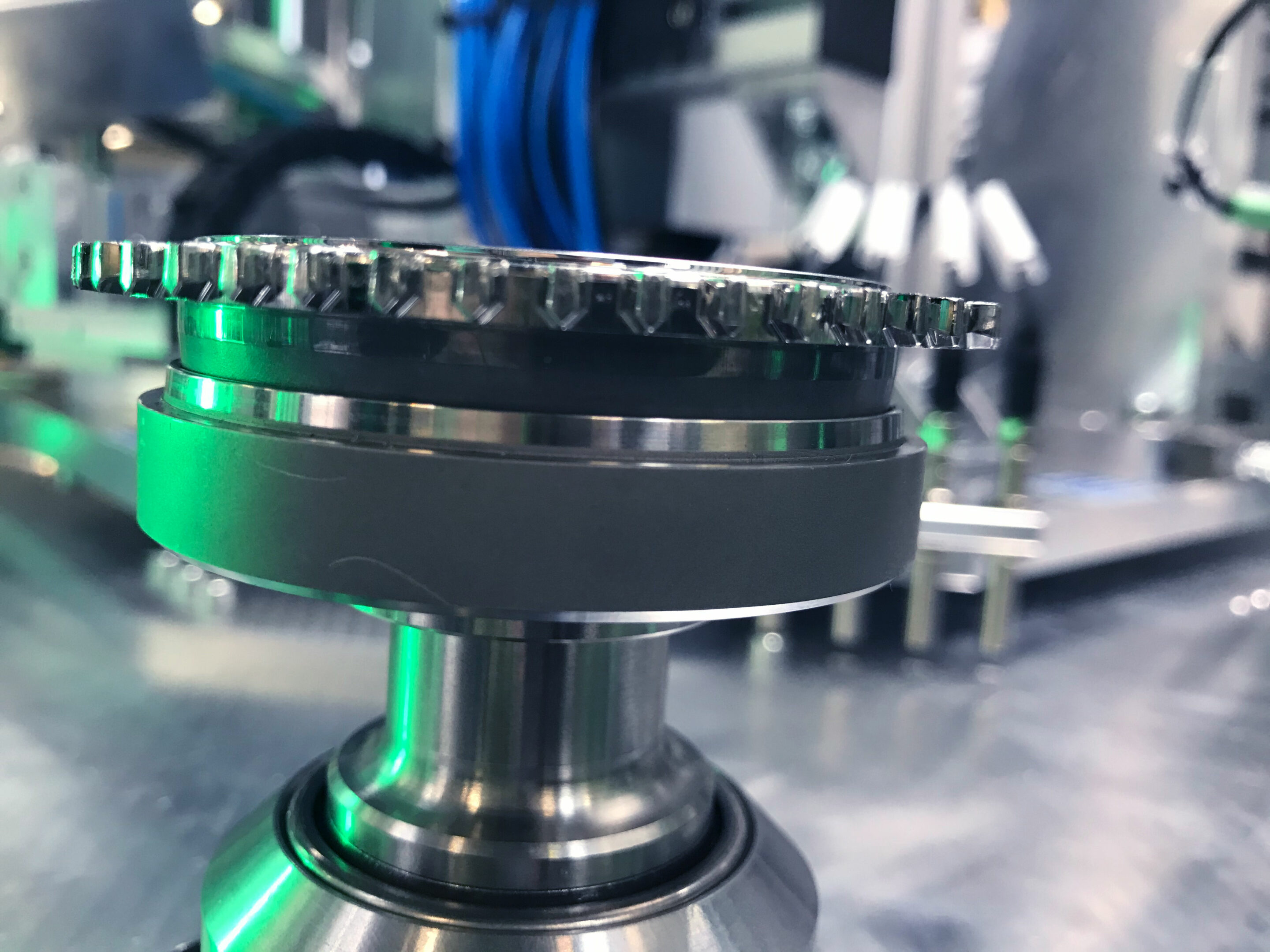

For battery manufacturer Varta Consumer Batteries, product quality is the key to competition. The interfaces for energy transfer, positive and negative pole, must comply with tight tolerance limits. If mechanical errors and performance deficiencies occur, the way into the world of mobile electrical devices remains blocked. But detecting faults is only one side of the coin. The big challenge is to keep the percentage of pseudo rejects as low as possible.

Implementation

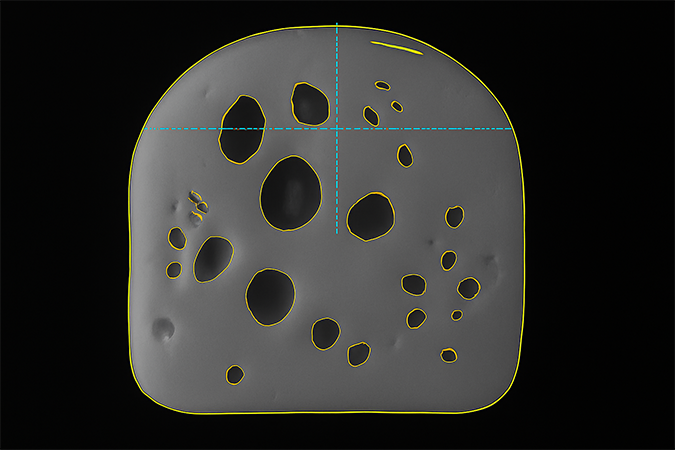

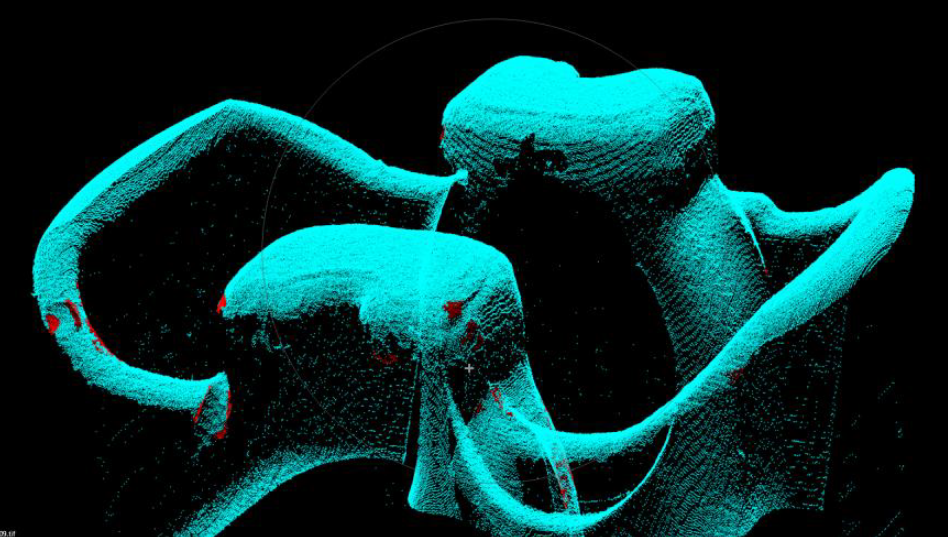

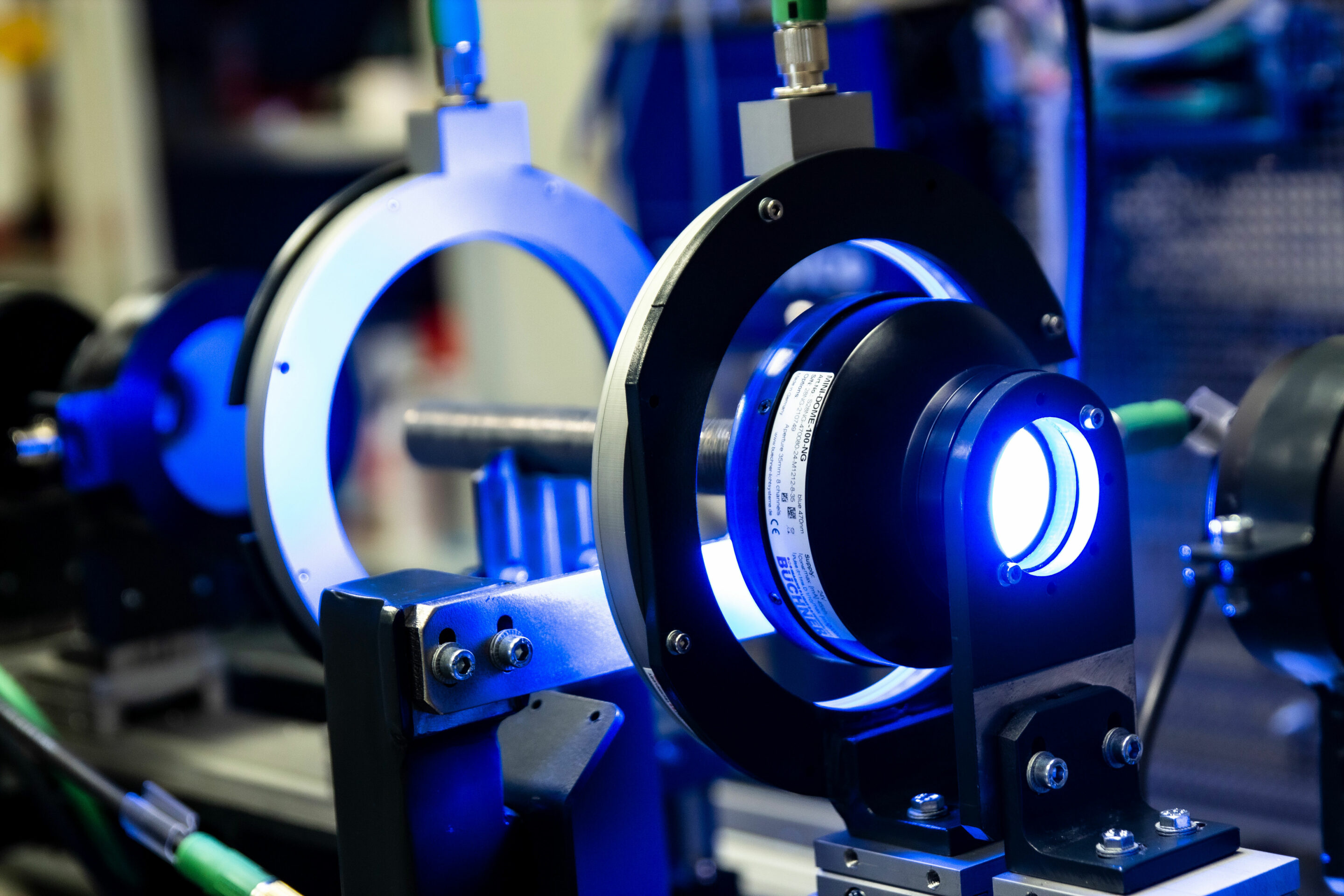

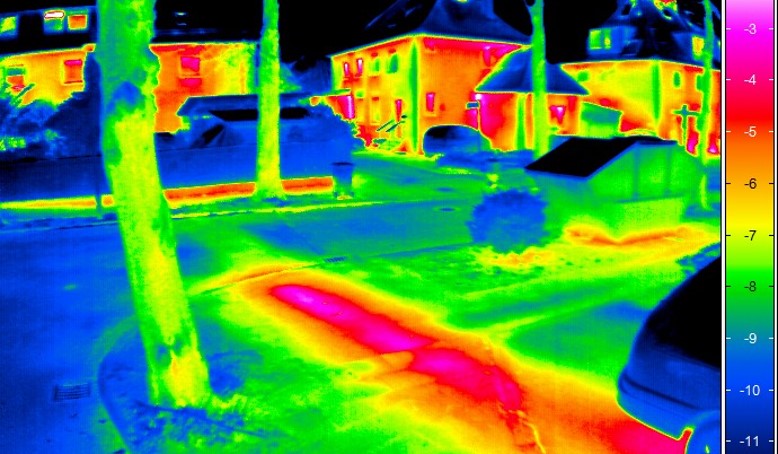

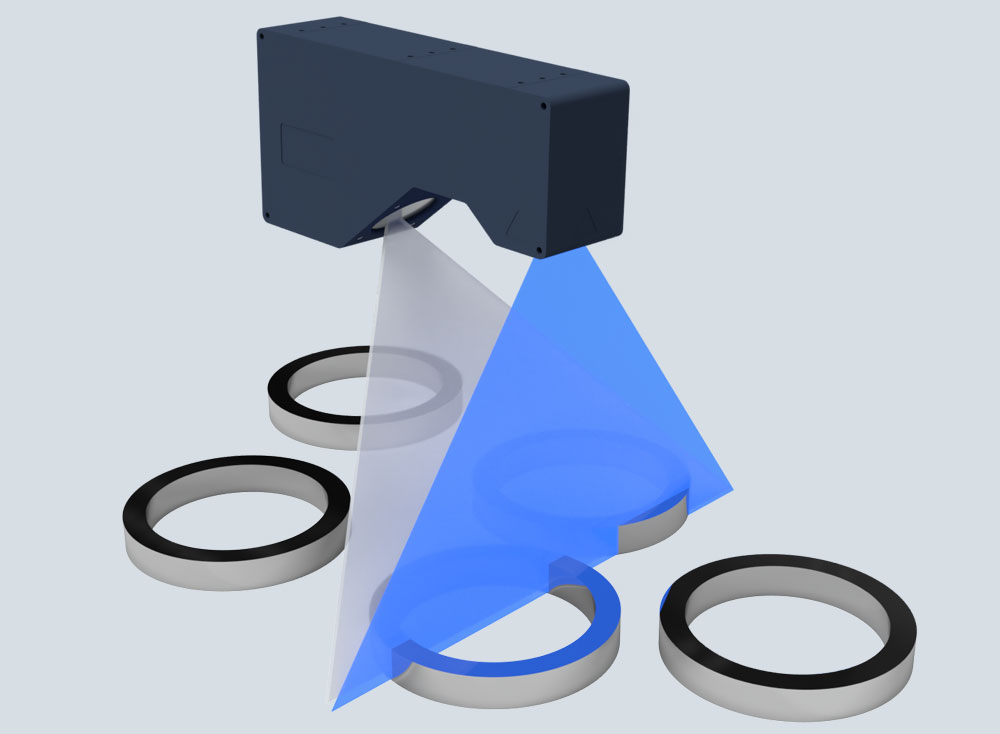

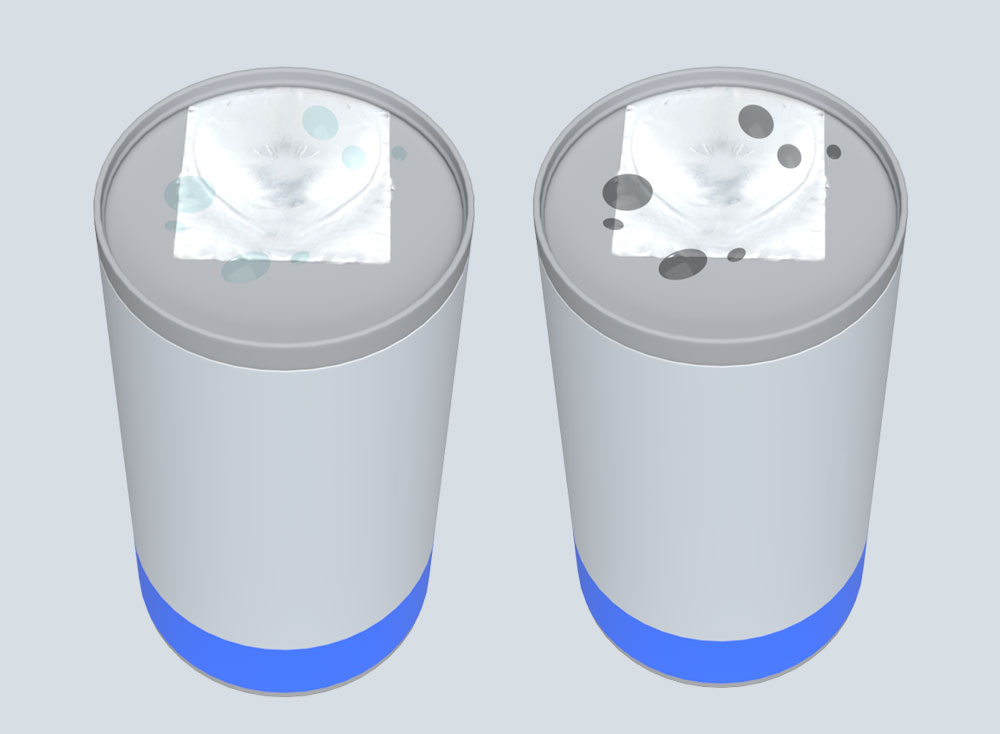

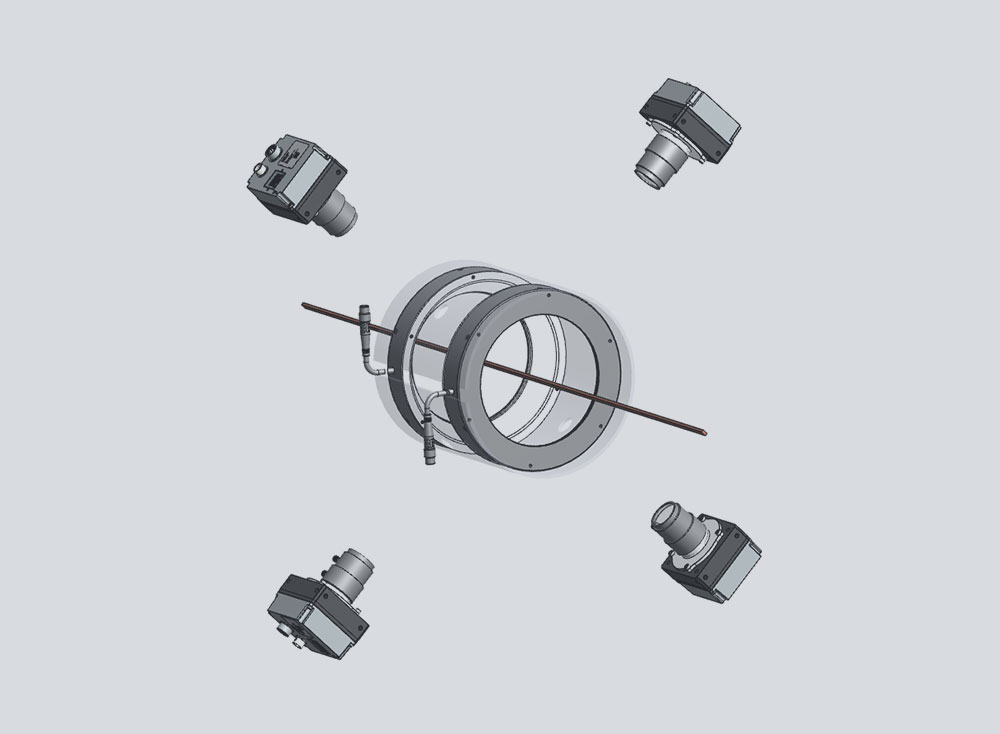

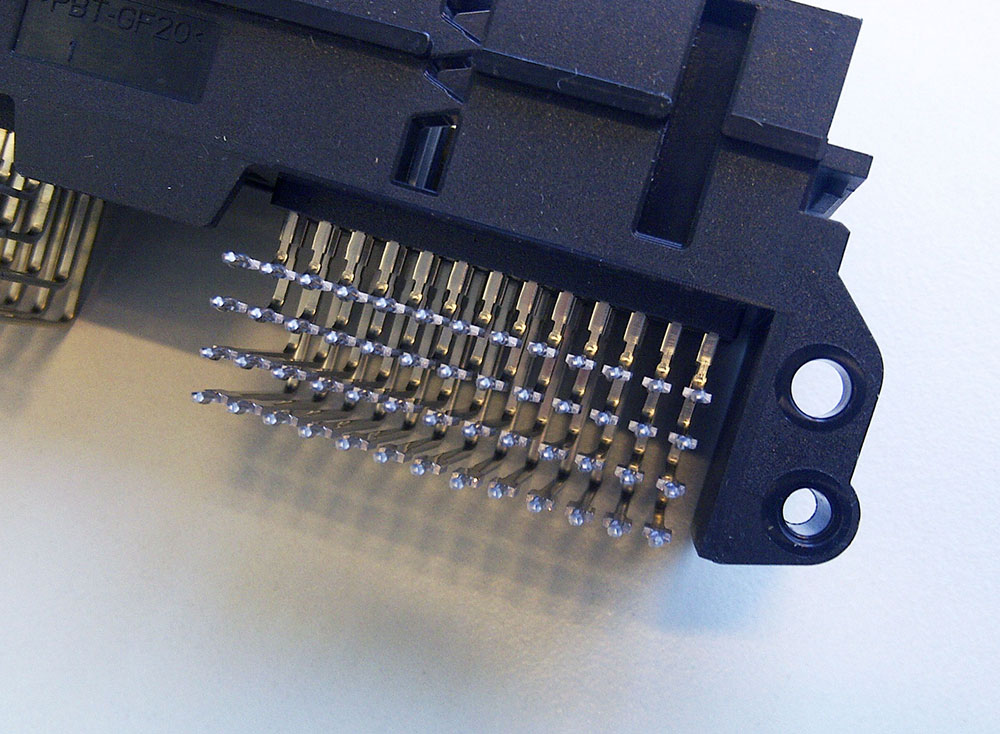

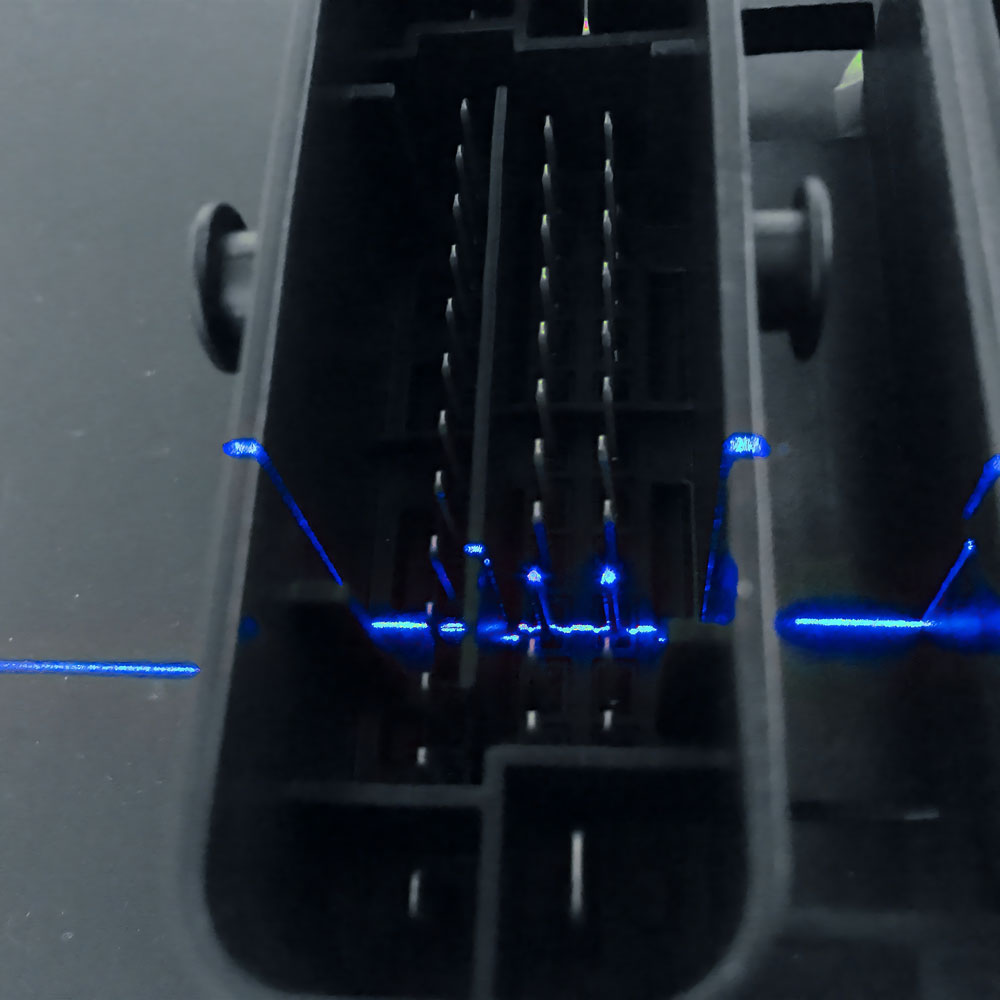

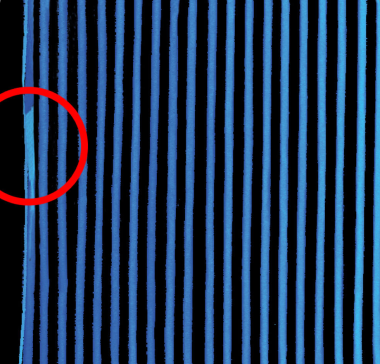

2D cameras with classic dome illumination identify contamination on the battery poles with tightly defined tolerance limits. However, 2D systems reach their limits when it comes to differentiating between contamination and mechanical defects. Particularly challenging are the demanding reliefs of the battery poles and the associated variety of reflections.

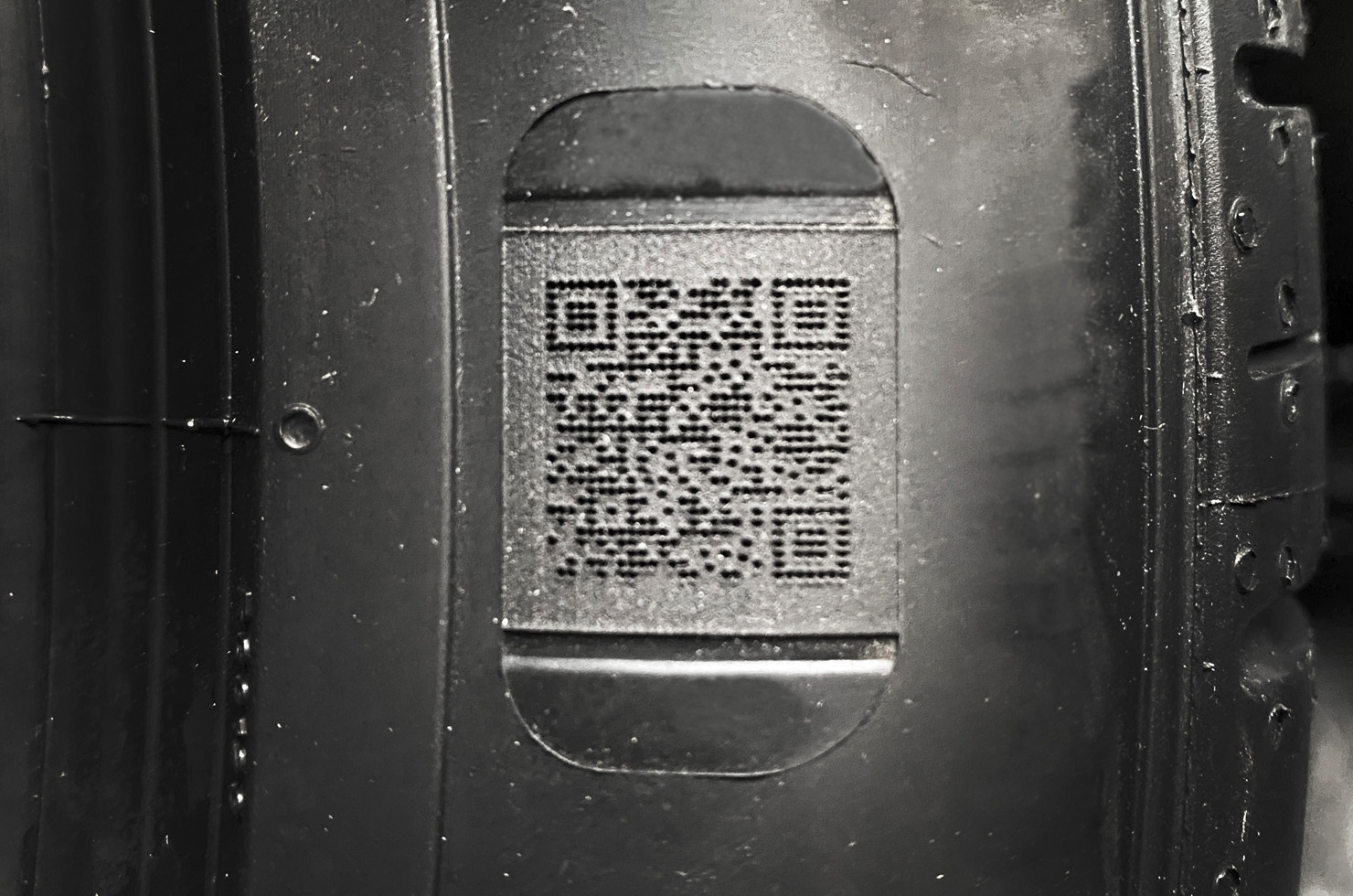

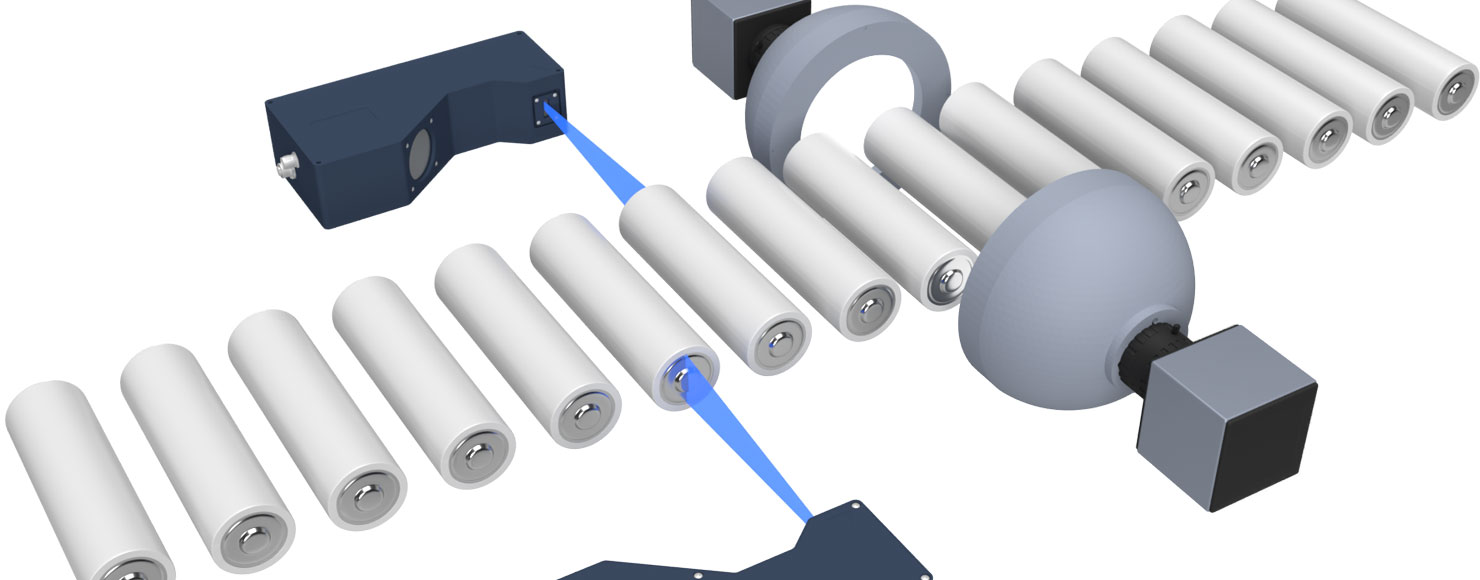

This is remedied by a 3D camera system, which makes it easy to differentiate between the two inspection characteristics. Distinguishing between contamination and mechanical defects can be done with histogram and blob evaluation. The inspection systems make results of the optical inspection available to the PLC within only 0.06 seconds. This subsequently ensures that defective parts are reliably ejected from the process.

Parameters

- 1000 batteries/min

- Result provision for PLC within 0.06 sec

Customer benefits

The combination of 2D and 3D systems creates the perfect balance between 100% error detection and minimal ejection of supposedly defective good parts. A personnel-intensive, manual visual inspection is no longer necessary. Last but not least, the minimized reject rate contributes to securing Germany as a business location in the long term.

Your contact person

Christian Merten

Head of Sales

Email: c.merten@aku.eu

Phone: +49 151 / 259 190 10

Case studies

You might also be interested in:

Machine vision systems from aku.automation GmbH have a modular design.

Existing solutions can be easily scaled and extended. They form the basis for customized solutions. In particular, full flexibility in the choice of imaging sensor technology allows you to implement the best and most reliable application on the market. Talk to us – our consultants will be happy to answer your questions.