Case studies

Efficient parcel logistics: machine vision for fast deliveries

Logistics

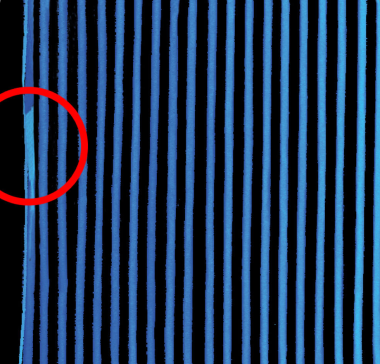

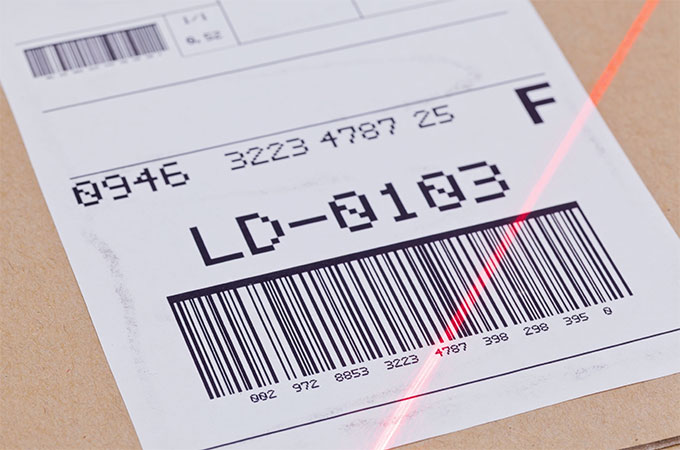

Code verificationSurface inspection

2D technology

Initial situation

Modern delivery services and retail facilities must be able to handle the rapid processing of parcels for prompt delivery. Customers expect items within 24 hours or less, requiring complex logistics systems. Machine vision solutions ensure speedy delivery, from goods logistics to parcel loading.

Implementation

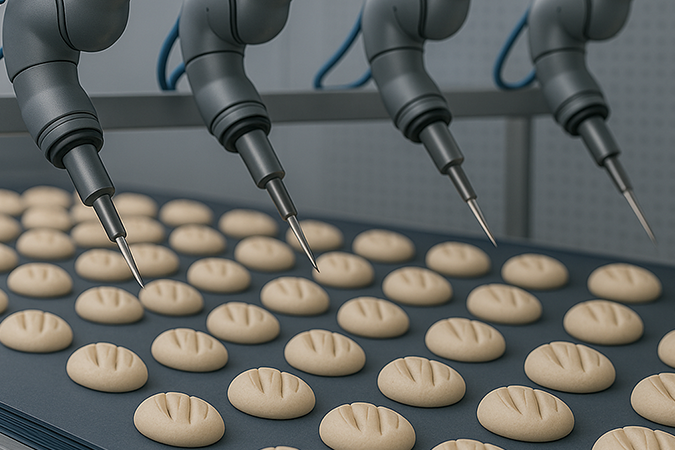

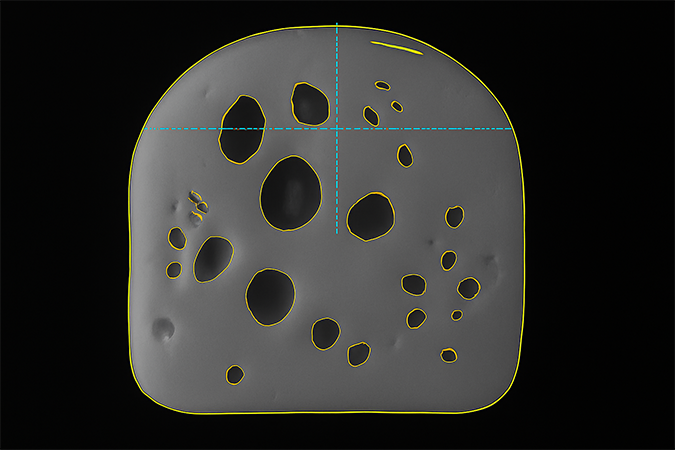

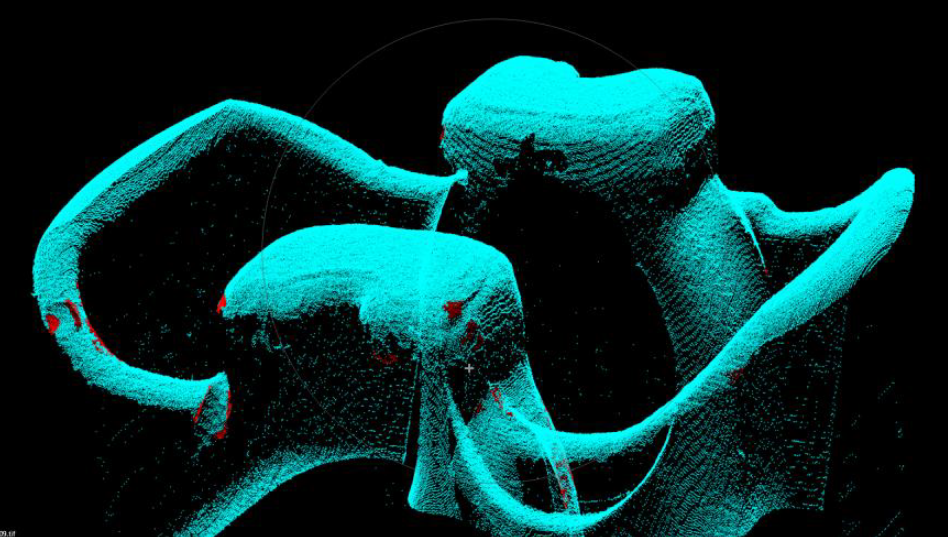

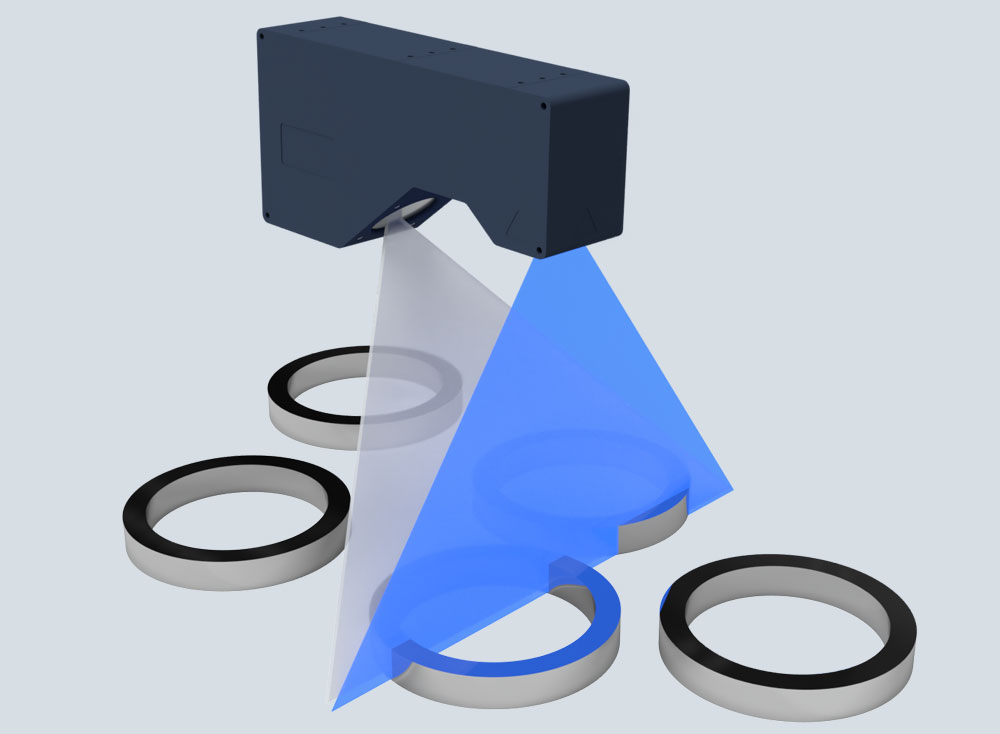

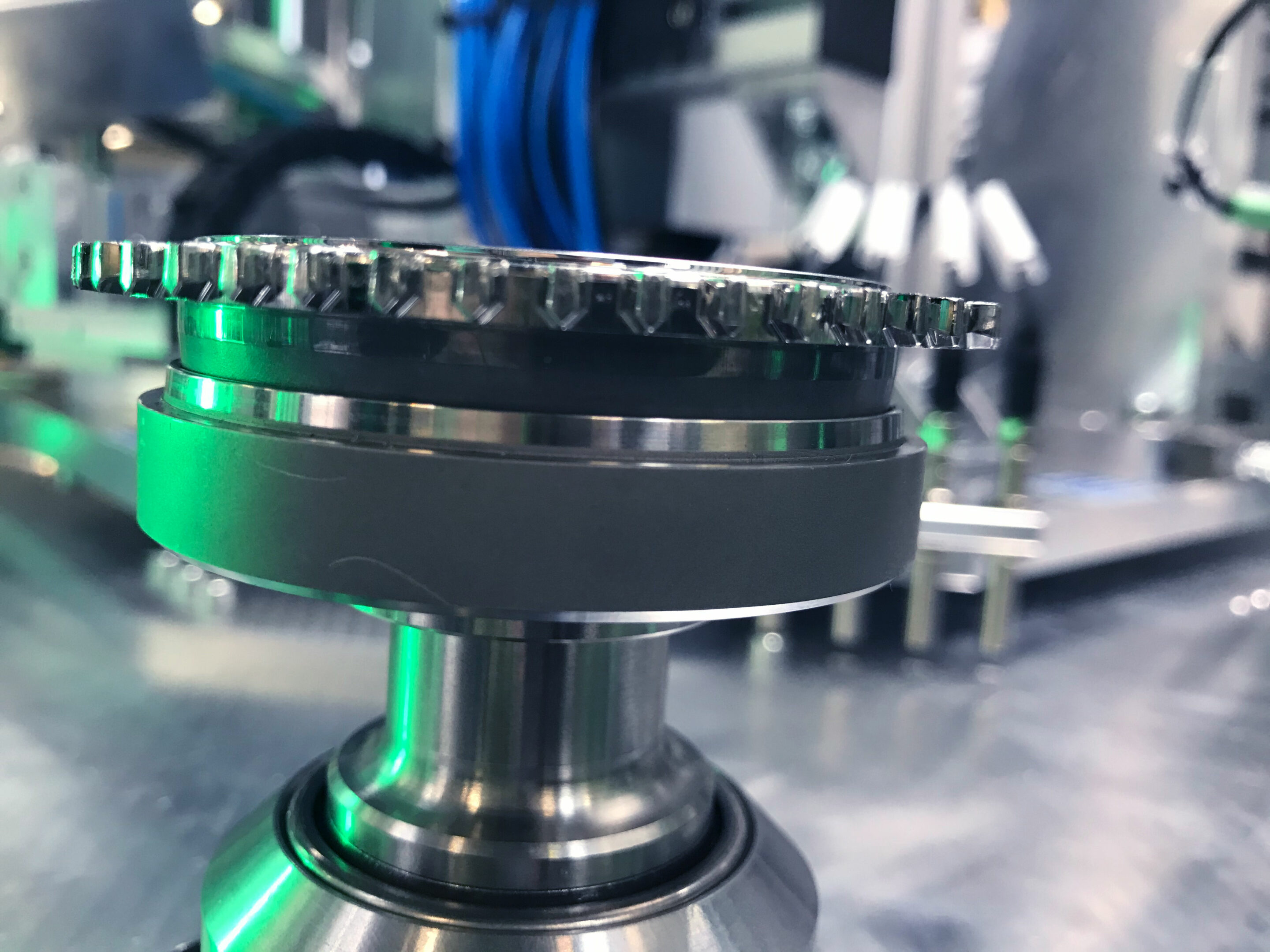

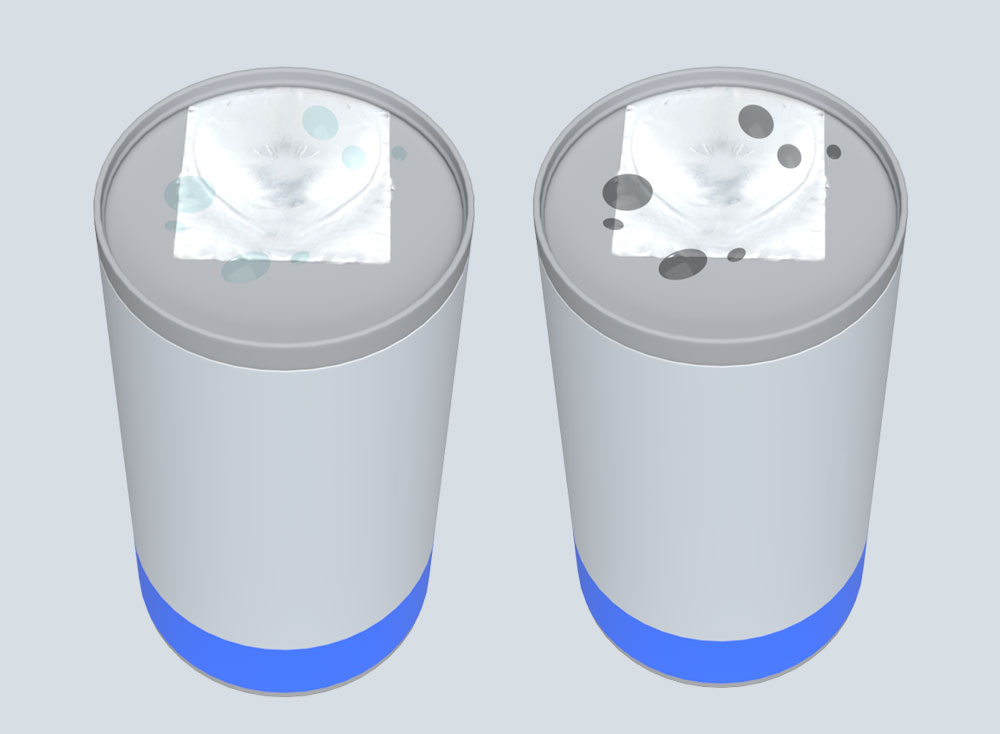

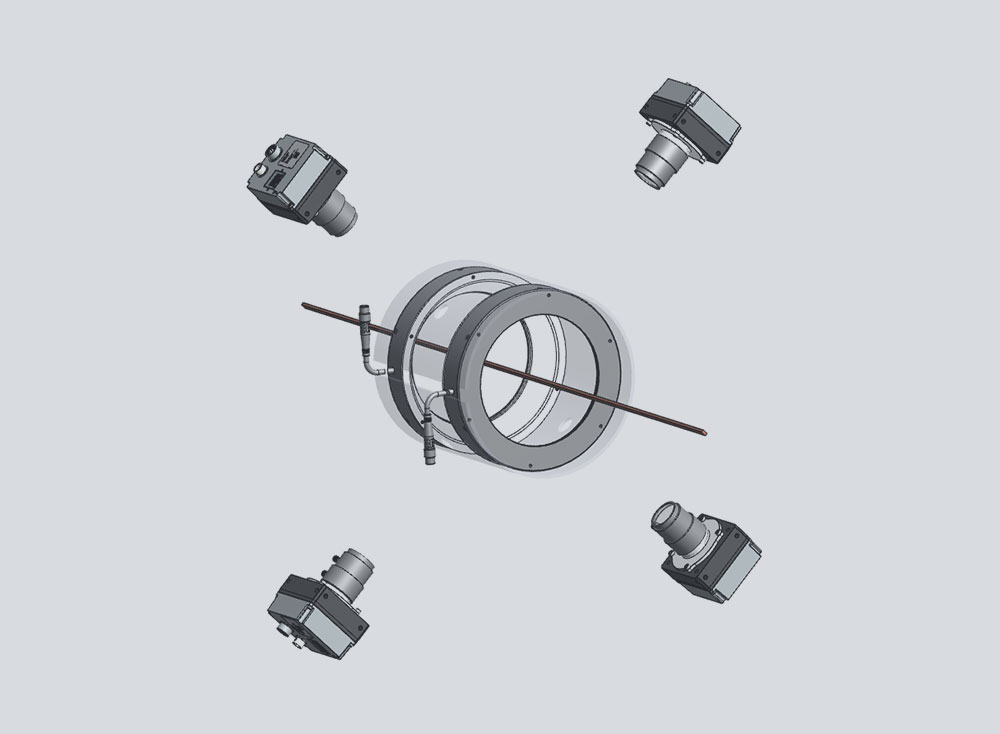

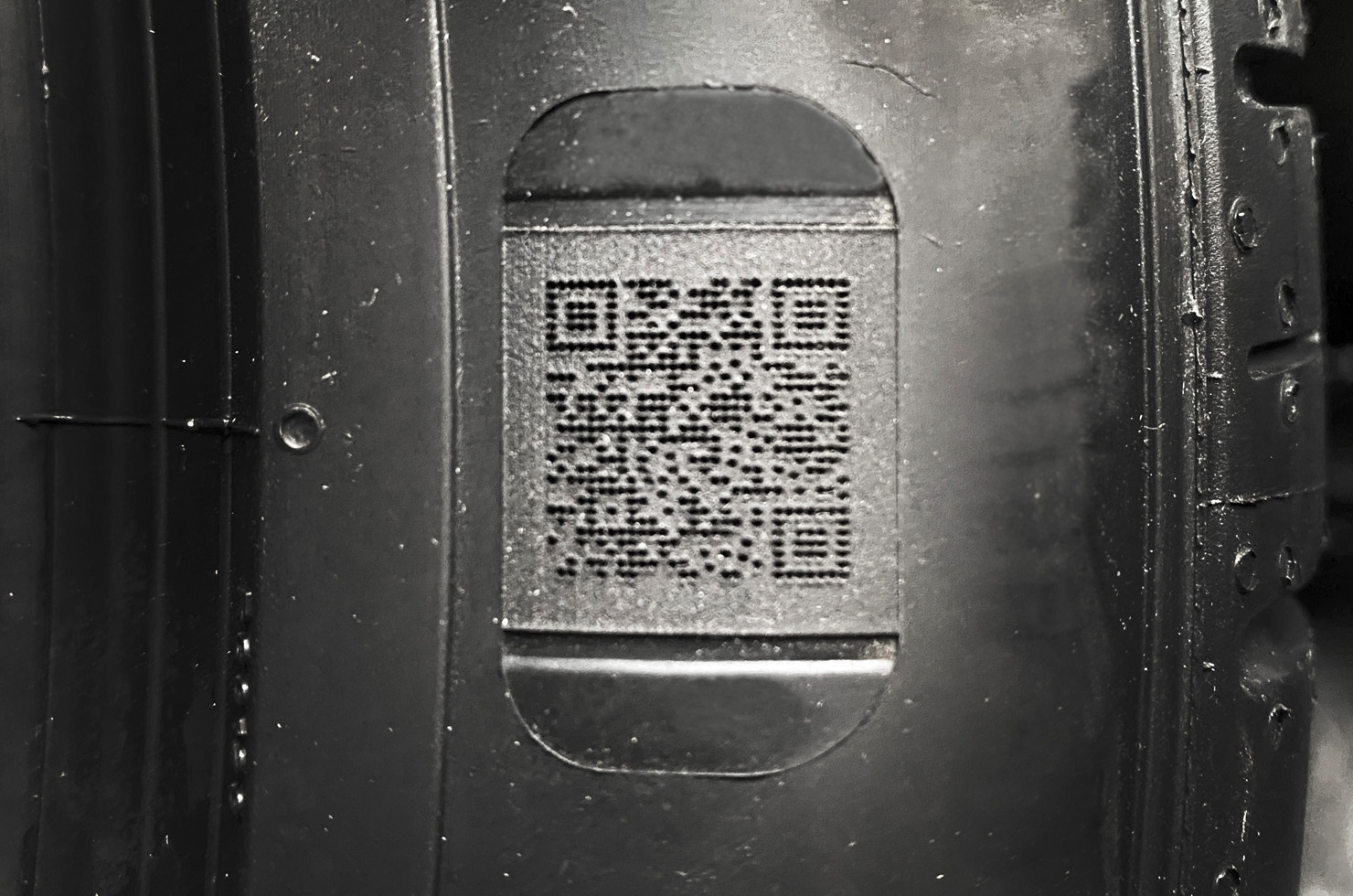

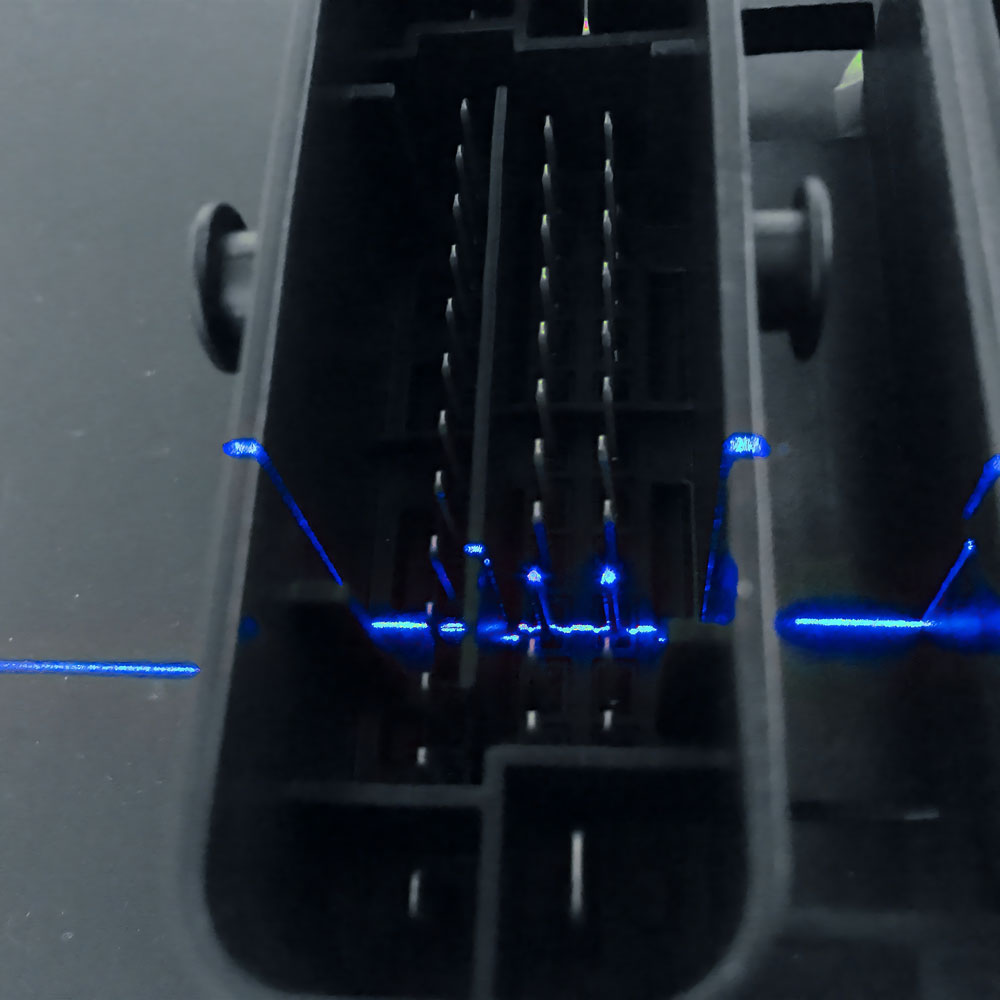

In the distribution center of a delivery company, incoming parcels are placed on a conveyor belt, where they are brought into the correct distance and orientation to each other. With the help of machine vision and deep learning, the parcels are scanned and assigned to the correct items.

This intelligent assignment is based on zip codes that are noted on the parcel labels. The technology-based measure significantly increases the efficiency of the entire logistics system. Once the allocation process has been successfully completed, the parcels are discharged from the conveyor belt via a chute. The parcels are then loaded into the designated delivery vans in preparation for delivery to the end customer.

Parameters

- 4x 2D area scan camera

Customer benefits

Machine vision speeds up parcel processing and delivery. Customers benefit from faster deliveries, greater satisfaction and more efficient processes. The technology optimizes logistics systems, increases performance and enables smooth deliveries to the doorstep.

Your contact person

Christian Merten

Head of Sales

Email: c.merten@aku.eu

Phone: +49 151 / 259 190 10

Case studies

You might also be interested in:

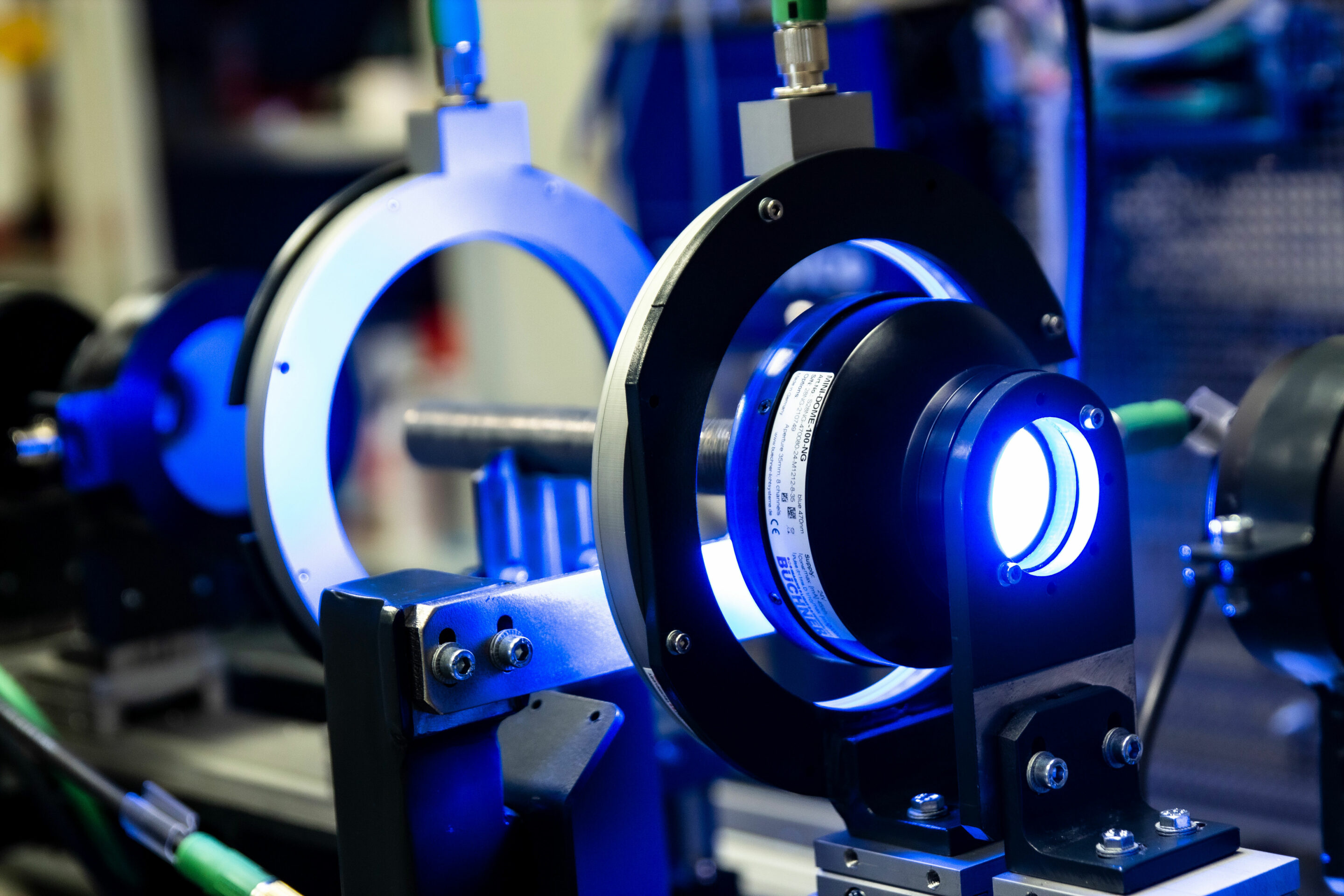

Machine vision systems from aku.automation GmbH have a modular design.

Existing solutions can be easily scaled and extended. They form the basis for customized solutions. In particular, full flexibility in the choice of imaging sensor technology allows you to implement the best and most reliable application on the market. Talk to us – our consultants will be happy to answer your questions.