Case studies

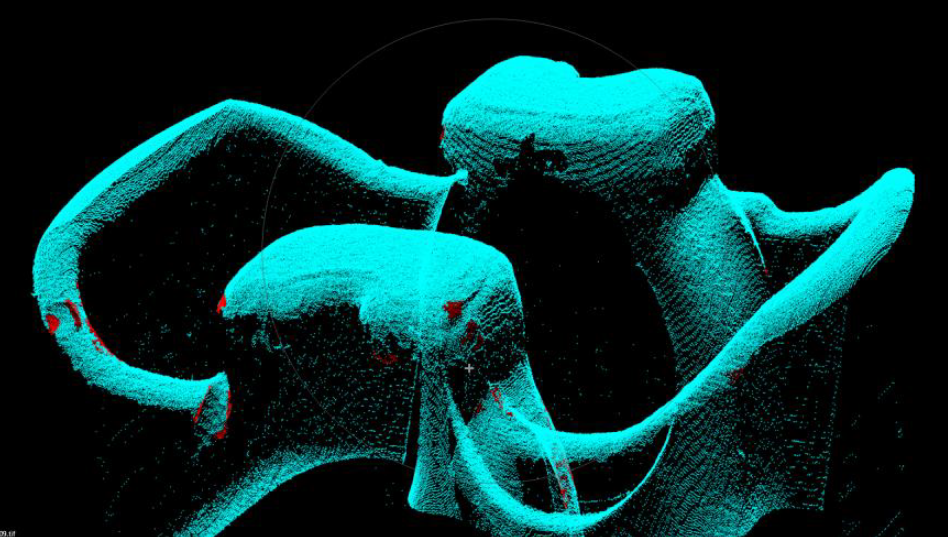

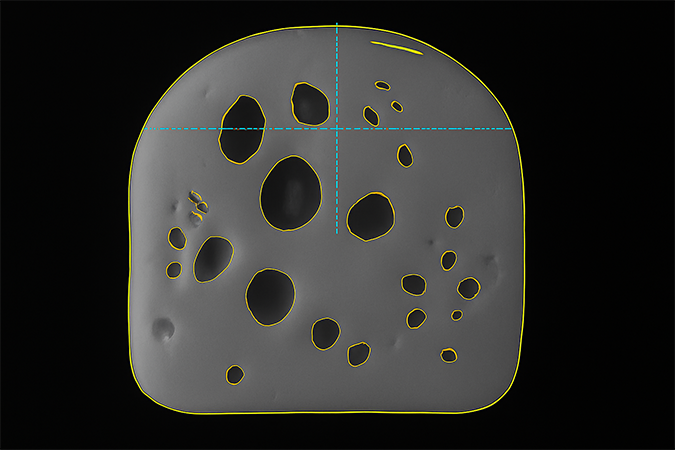

Sectional image inspection of cheese slices

Food & Beverages

MeasurementPresence control

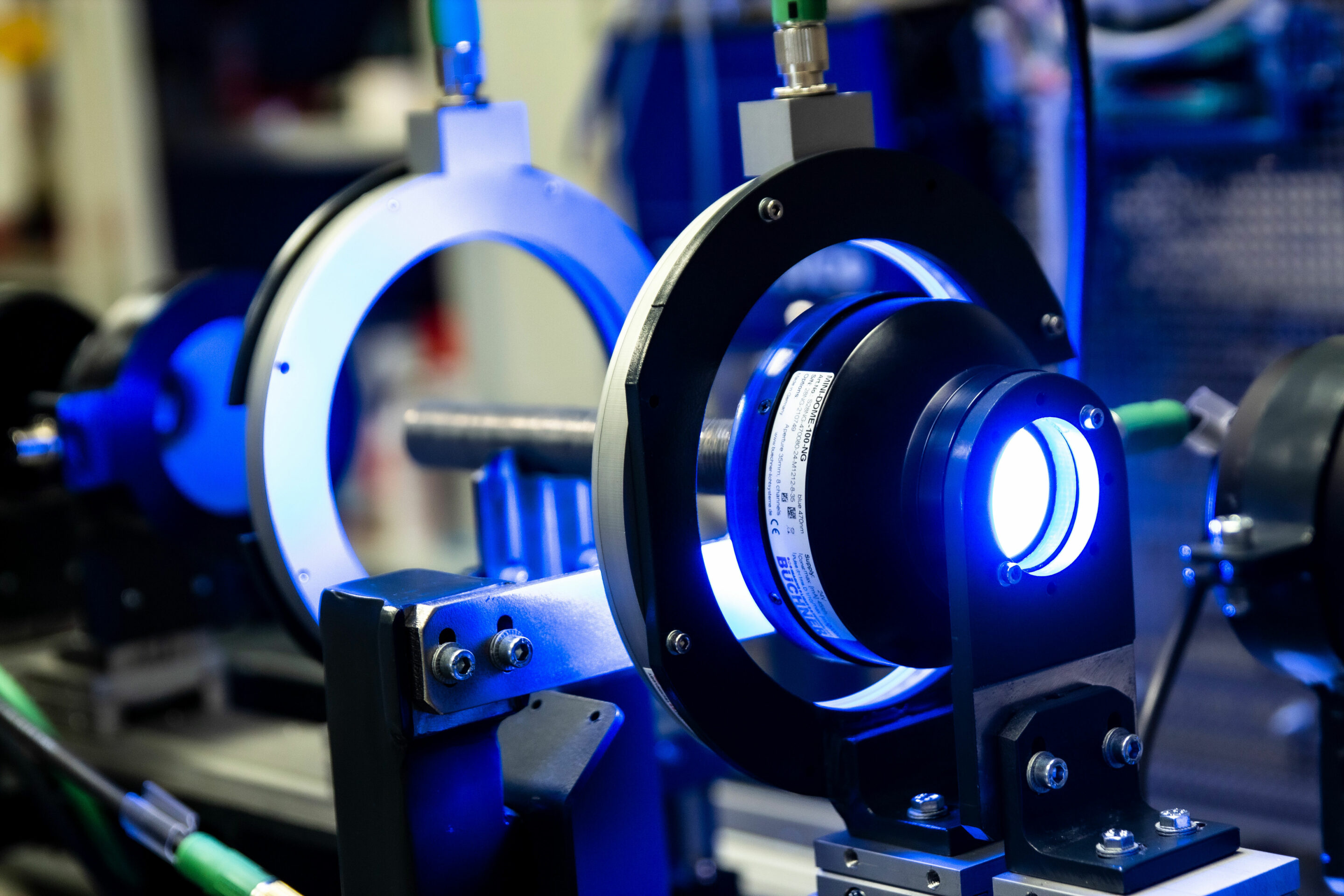

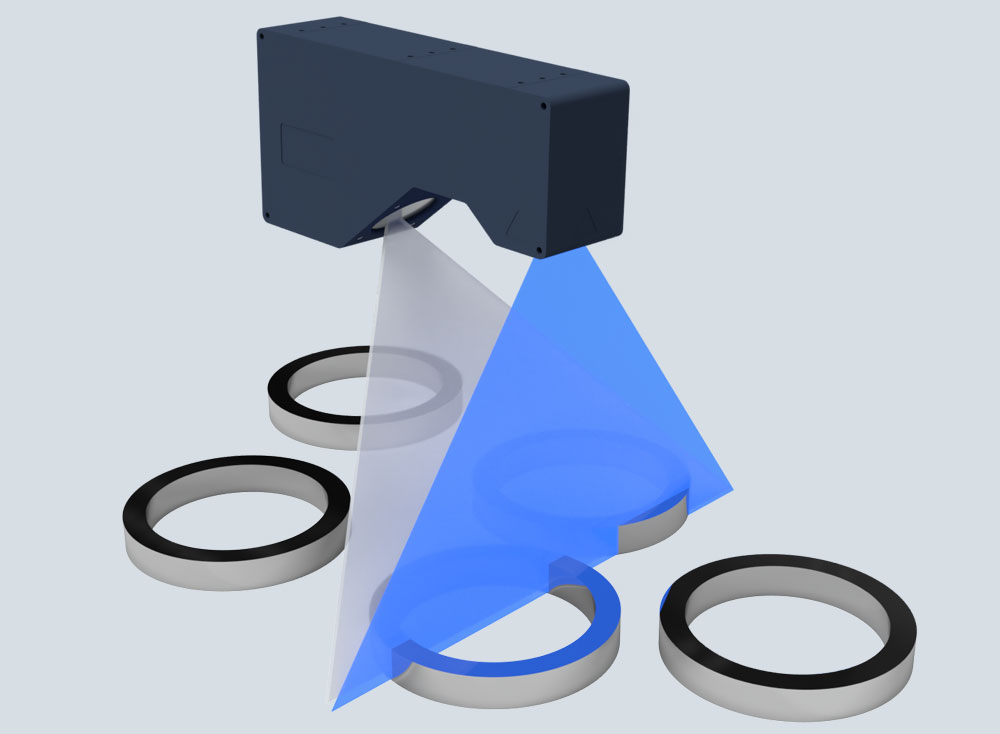

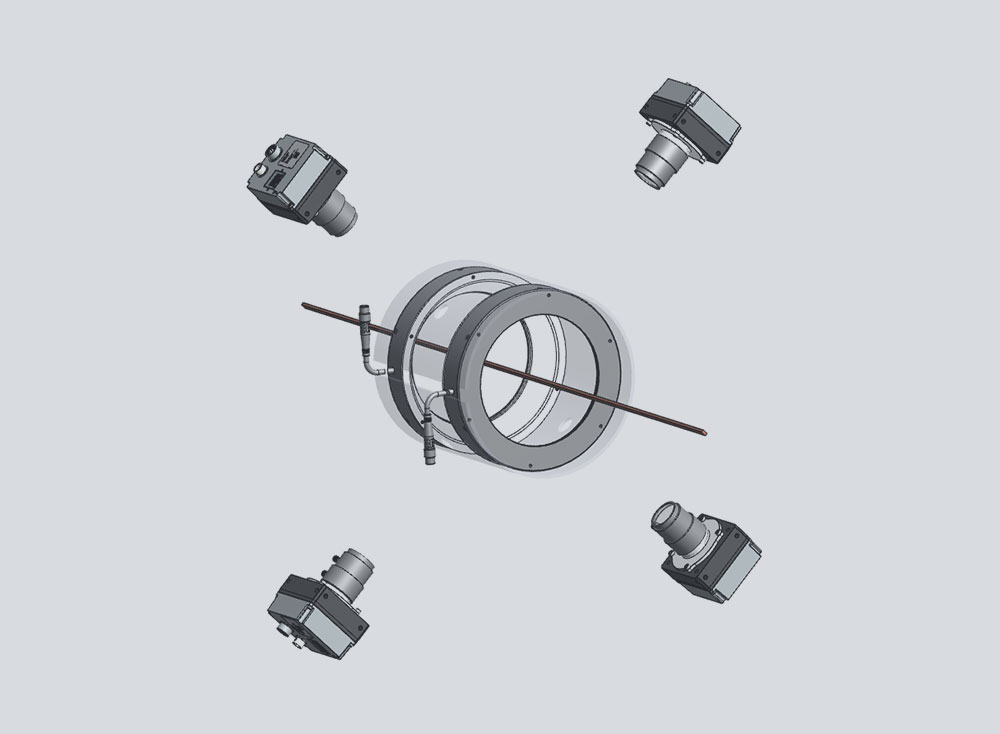

Line scan camera

Initial situation

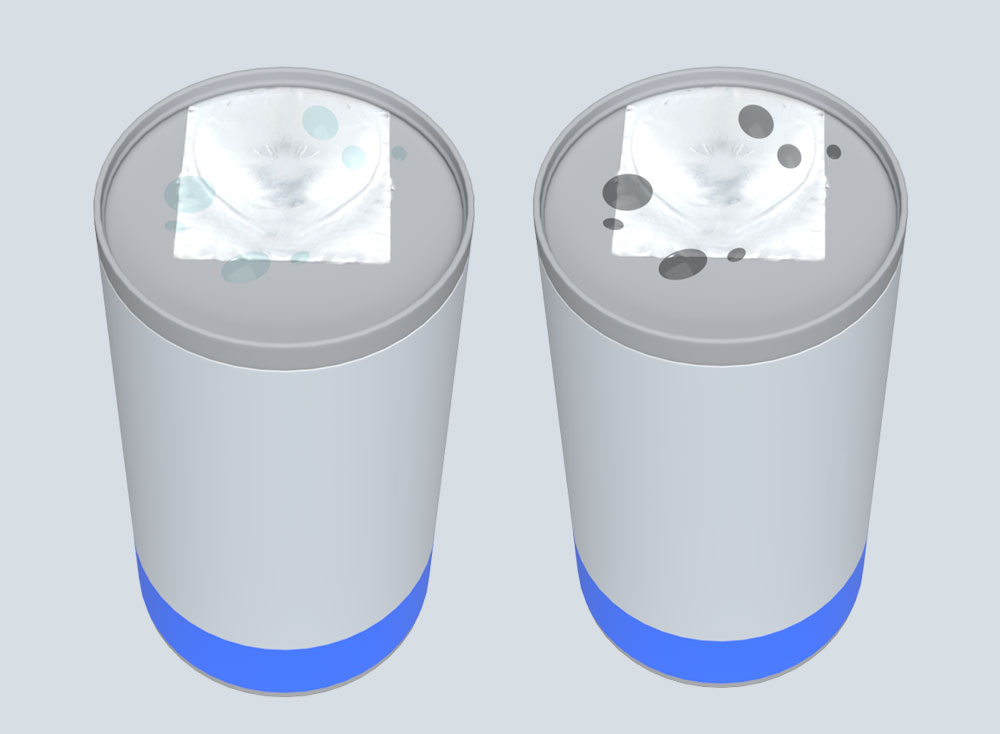

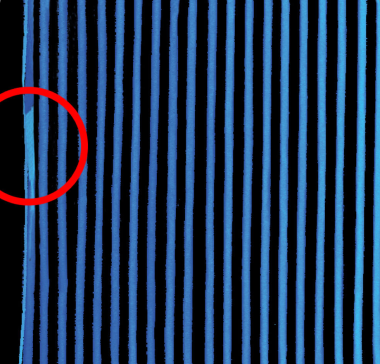

Visual quality plays a central role in the production of cheese slices. Attributes such as the characteristic hole pattern, freedom from cracks and an even distribution of herbs or pepper are particularly important. Visual deviations lead to rejects, complaints and cost-intensive reworking. Automated, reliable inline inspection is therefore essential for stable processes and verifiable quality.

Implementation

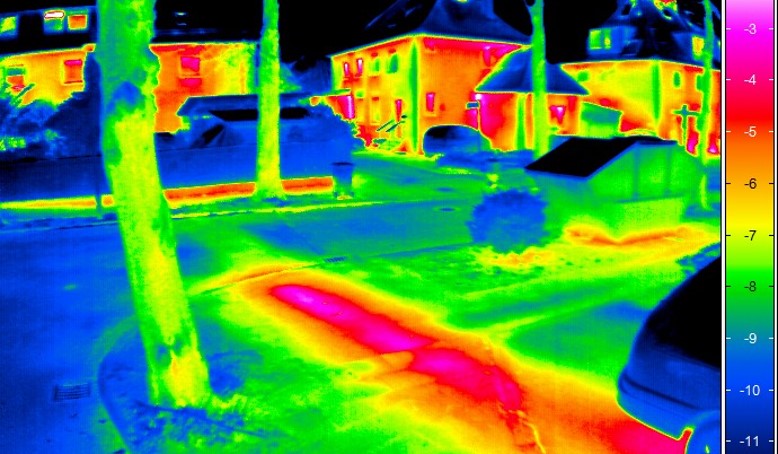

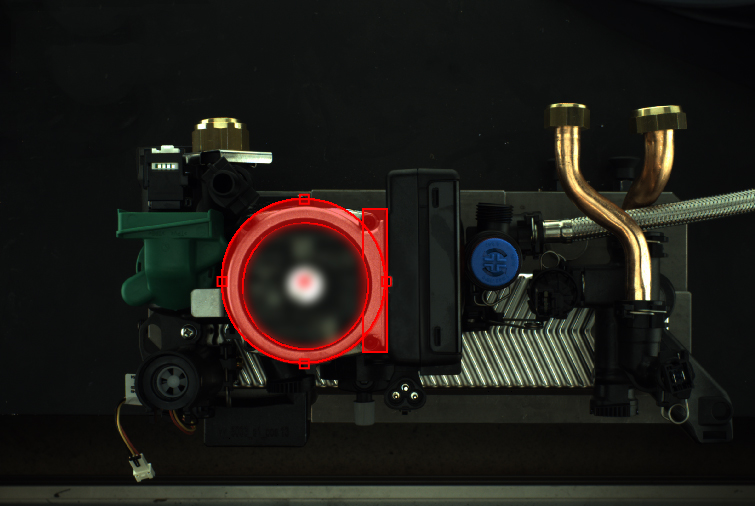

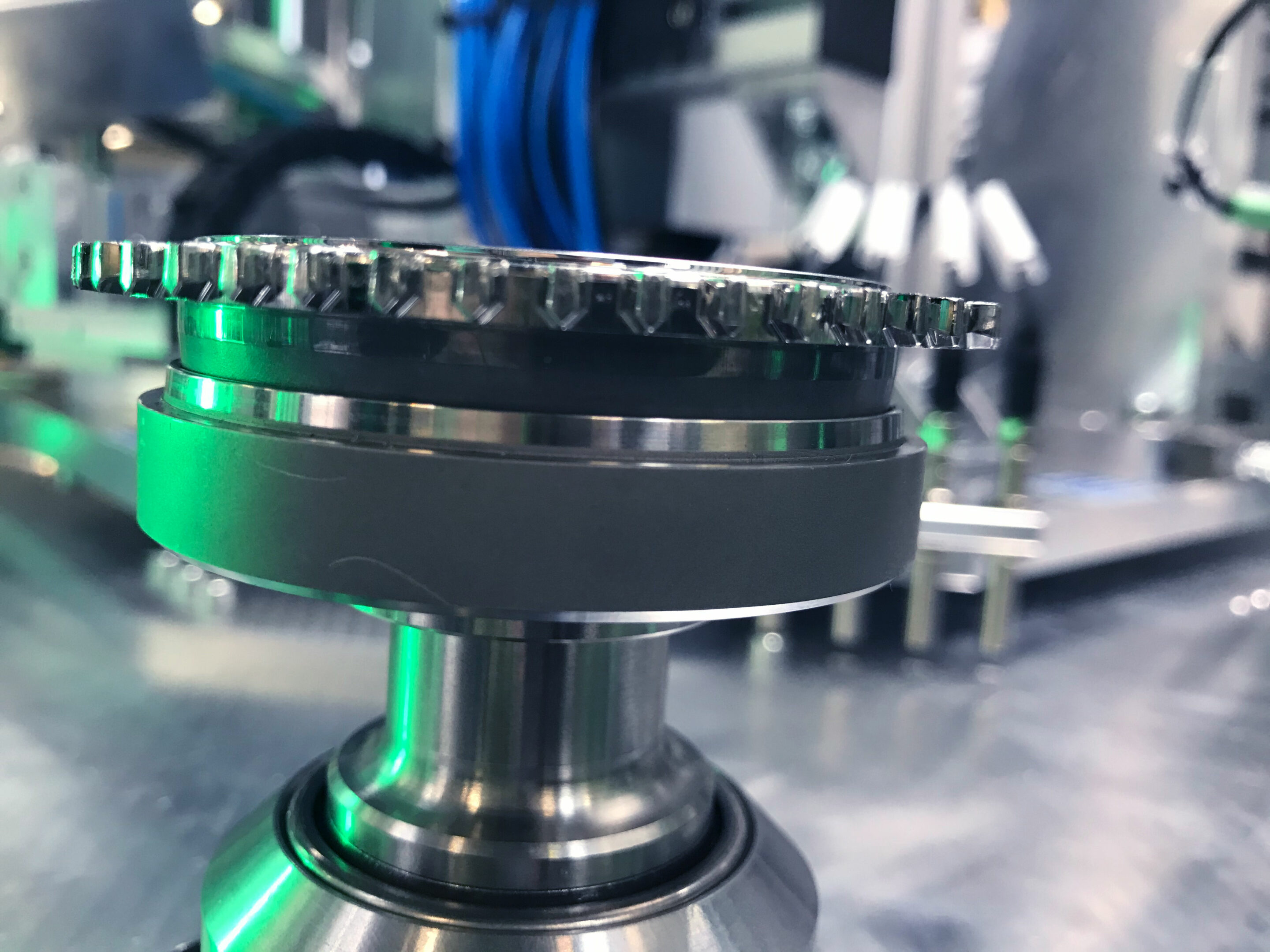

The inspection system is based on a high-resolution line scan camera that captures the entire cheese slice during the conveying process. Our aku.visionManager® software analyzes each image with regard to defined quality features. These include cracks, large and small holes, the total hole area, the characteristic archway shape and the distribution of spices such as herbs or pepper. The pane is virtually divided into zones to enable a differentiated surface evaluation. Irregularly shaped structures such as whey nests are also reliably detected.

Processing takes place continuously without the product having to be stopped or ejected. All test results are automatically transferred to the customer’s system and are available for batch statistics and traceability.

Parameters

- Evaluation: up to 45 slices/minute

Customer benefits

Thanks to automated quality control in the production flow, faulty batches can be detected at an early stage and minimized. At the same time, complete traceability is guaranteed without the need for additional personnel. The solution is robust, highly accurate and can be easily integrated into existing lines. This sustainably increases production stability, efficiency and product quality.

Your contact person

Christian Merten

Head of Sales

Email: c.merten@aku.eu

Phone: +49 151 / 259 190 10

Case studies

You might also be interested in:

Machine vision systems from aku.automation GmbH have a modular design.

Existing solutions can be easily scaled and extended. They form the basis for customized solutions. In particular, full flexibility in the choice of imaging sensor technology allows you to implement the best and most reliable application on the market. Talk to us – our consultants will be happy to answer your questions.